当前标签:Roll-Forming-Machine-Factory

Roll-Forming-Machine-Factory为你详细介绍

Roll-Forming-Machine-Factory的分类,包括

Roll-Forming-Machine-Factory下的所有网站建设及优化的方法、技巧、服务流程价格。同时我们还为您精选了

Roll-Forming-Machine-Factory分类的行业资讯、价格行情等,在全国地区获得用户好评,欲了解更多详细信息,请点击访问!

-

Fluorescent lighting remains a widely used solution in commercial, industrial, and institutional environments. While LED technology has gained prominence, fluorescent fixtures still serve key roles in certain applications due to their cost-···

-

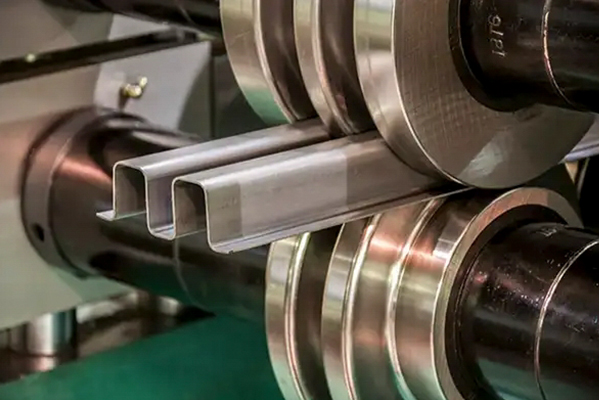

In the lighting manufacturing industry, efficiency, precision, and product quality are essential to stay competitive. Advanced roll forming equipment has become a vital asset for lighting producers looking to optimize their production lines···

-

Choosing the right roll forming solution provider is a critical decision for manufacturers and fabricators. The right partner can improve production efficiency, reduce costs, and ensure high-quality output. Buyers should evaluate several ke···

-

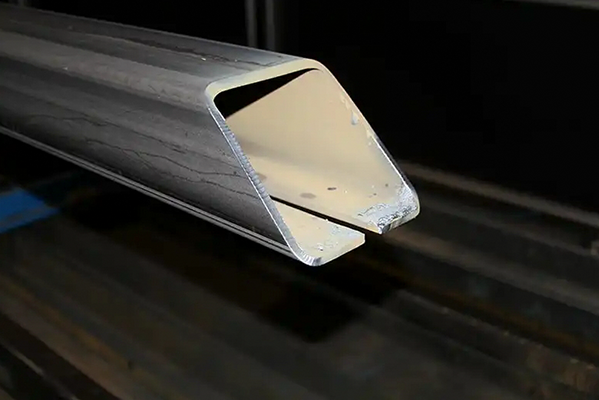

Roll forming technology has evolved significantly, offering manufacturers a versatile and efficient method for producing metal components. As industries demand more customized and precise parts, advanced roll forming systems have adapted to···

-

When it comes to shaping sheet metal with accuracy and consistency, roll forming machines play a key role. These machines are widely used in industries like automotive, construction, and appliance manufacturing because they offer reliable a···

-

Roll forming is a continuous bending process used to shape metal coils into desired profiles. The speed of roll forming is a critical factor that impacts production efficiency, product quality, and overall cost-effectiveness. Understanding ···

-

Roll forming is a widely used metal shaping process that involves continuously bending a long strip of metal through a series of rollers to achieve a desired cross-sectional profile. While this method offers advantages such as high producti···

-

Roll forming is a highly precise metal fabrication process used to create continuous profiles with consistent cross-sections. Achieving the desired dimensional accuracy requires strict adherence to tolerance standards. This article discusse···

-

Roll forming is a highly efficient metal shaping process that offers numerous advantages for manufacturers across various industries. This continuous bending operation transforms metal coils or sheets into precise cross-sectional profiles w···

-

Roll forming is a widely used manufacturing process that involves continuously bending a long strip of metal into a desired cross-sectional profile. Among its various advantages, one key benefit stands out: consistent precision in high-volu···

-

Roll forming is a continuous metal forming process that has become essential in modern manufacturing. This efficient method transforms flat metal sheets or coils into desired cross-sectional profiles through a series of bending operations. ···

-

Roll forming is a continuous metal forming process that transforms flat metal strips or coils into desired cross-sectional profiles by passing them through a series of rolling stations. This method is widely used in manufacturing due to its···

-

Roll forming is a widely used manufacturing process in industries like construction, automotive, and appliance manufacturing. It involves feeding a continuous strip of metal into a series of rollers, which progressively shape the material i···

-

Roll forming is a continuous metalworking process used to shape thin sheet metal into desired profiles through a series of rolls. This technique is commonly employed in the manufacturing of metal products with specific cross-sectional shape···

-

Aluminum is widely used in roll forming due to its favorable strength-to-weight ratio, workability, and surface finish potential. Selecting an appropriate aluminum grade depends on the desired balance between formability, strength, corrosio···