Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Jun 08, 2025 Visit:93 Source:Roll Forming Machine Factory

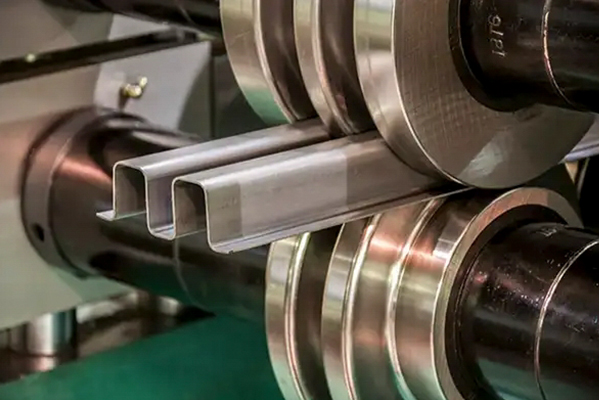

Roll forming technology has evolved significantly, offering manufacturers a versatile and efficient method for producing metal components. As industries demand more customized and precise parts, advanced roll forming systems have adapted to meet these diverse production requirements. This article explores how modern roll forming technology addresses various manufacturing needs while maintaining efficiency and quality.

Precision and Customization

One of the key advantages of advanced roll forming is its ability to produce highly precise and customized profiles. Unlike traditional methods, modern roll forming machines can shape metal with tight tolerances, ensuring consistency across large production runs. The flexibility in tooling design allows manufacturers to create complex cross-sections tailored to specific applications, from automotive components to construction materials.

High-Speed Production Capabilities

Efficiency is a critical factor in manufacturing, and roll forming excels in high-speed production. Advanced systems can process metal coils at rapid speeds while maintaining dimensional accuracy. This capability is particularly beneficial for industries requiring large volumes of uniform parts, such as appliance manufacturing or structural framing. By minimizing material waste and reducing secondary operations, roll forming enhances overall productivity.

Material Compatibility

Modern roll forming technology supports a wide range of materials, including steel, aluminum, and specialty alloys. This adaptability enables manufacturers to select the most suitable material for their application without compromising production efficiency. Additionally, advancements in roll forming allow for the processing of pre-coated or pre-finished metals, reducing the need for post-production treatments.

Adaptability to Changing Demands

Manufacturing requirements often shift due to design updates or new industry standards. Advanced roll forming systems can accommodate these changes with minimal downtime. Quick-change tooling and programmable controls enable manufacturers to switch between different profiles efficiently, making the technology ideal for both high-volume and low-volume production runs.

Cost-Effective Manufacturing

By integrating automation and precision engineering, roll forming reduces labor costs and material waste. The continuous nature of the process ensures minimal scrap, while consistent quality lowers the risk of defects and rework. These factors contribute to a more cost-effective production method compared to alternative metal-forming techniques.

Conclusion

Advanced roll forming technology has proven its ability to meet diverse production requirements across multiple industries. With its precision, speed, material versatility, and adaptability, it remains a reliable solution for manufacturers seeking efficient and high-quality metal forming. As technology continues to advance, roll forming is expected to further enhance its capabilities, reinforcing its role in modern manufacturing.

By addressing key production challenges, roll forming ensures that manufacturers can deliver high-performance components while maintaining operational efficiency. Its continued evolution will likely keep it at the forefront of metal fabrication technologies.