Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:May 14, 2025 Visit:82 Source:Roll Forming Machine Factory

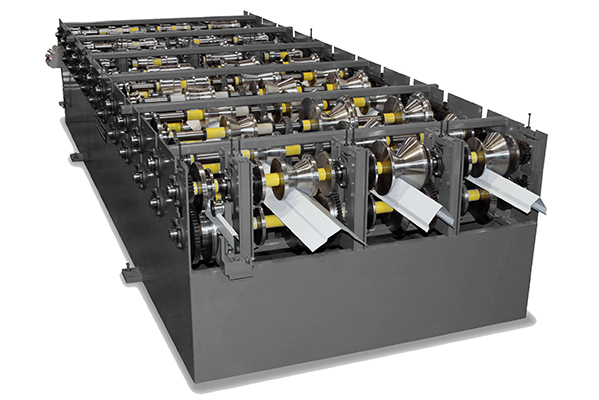

When it comes to roofing projects, professionals are always looking for ways to work smarter, not harder. The latest developments in gutter roll forming machines might just offer the practical improvements many contractors have been waiting for.

What Makes Modern Gutter Machines Different?

Today's gutter roll forming machines bring several thoughtful upgrades to roofing jobs:

They process materials with better precision, reducing wasted materials

Their adjustable settings handle different gutter profiles with simple changes

Improved feeding systems mean fewer jams and smoother operation

Compact designs take up less space at job sites or shops

These aren't revolutionary changes, but they add up to noticeable differences in daily work.

Practical Benefits for Roofing Professionals

Contractors using updated gutter machines report several advantages:

Consistent Results: The machines produce uniform gutter sections with reliable quality, important for professional installations.

Adaptable Production: Being able to switch between gutter styles quickly helps shops handle diverse customer requests.

Reduced Labor: Automated features minimize the heavy lifting and manual work traditionally involved in gutter forming.

Durability: Better construction means these machines withstand the demands of job site conditions.

Considerations Before Upgrading

While the improvements are meaningful, they may not be essential for every operation. Smaller shops with limited gutter work might find their current equipment sufficient. The decision often comes down to workload - operations processing significant gutter materials will notice the benefits more.

The Bottom Line

The latest gutter roll forming machines represent a solid step forward in making gutter production more efficient and less labor-intensive. For roofing professionals regularly working with gutters, these machines can help complete jobs with better consistency and less material waste. As with any equipment purchase, it's about matching the tool to your specific needs and workflow.

For those in the market, examining the specific features of different gutter roll forming machine models can reveal which might offer the right balance of performance and value for their operation.