Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:May 14, 2025 Visit:63 Source:Roll Forming Machine Factory

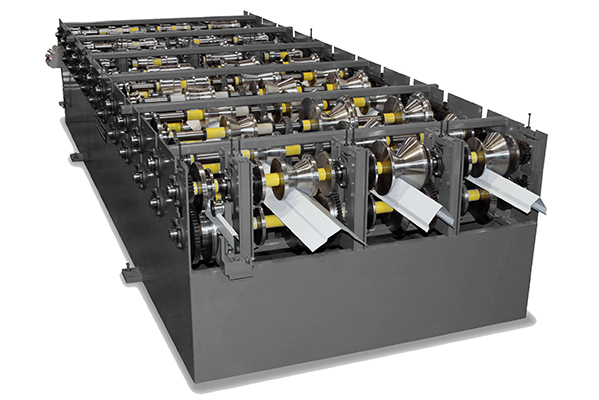

In the world of metal fabrication, gutter roll forming machines have always played an important role. Recently, there's been noticeable interest in narrow-width gutter roll forming equipment among professionals working with custom metal projects. Let's look at why this might be happening and what it means for shops considering their options.

Understanding Narrow-Width Gutter Machines

Narrow-width gutter roll forming machines are designed to handle smaller, more precise gutter profiles compared to standard equipment. These machines typically work with material widths that might be considered too small for conventional gutter formers, allowing for specialized applications where space or design requirements demand tighter dimensions.

Many operators find these machines useful when working on projects like:

Custom residential gutter systems

Specialty architectural details

Small-scale commercial applications

Repair and replacement work where existing structures limit size options

Why Some Shops Are Considering Narrow Models

Several factors appear to be driving interest in these specialized machines. First, the ability to work with narrower materials opens up design possibilities that weren't as easily achievable before. This can be particularly valuable when matching existing architectural features or meeting specific client requests.

Second, smaller profile machines often require less floor space in the shop, which can matter for operations working in tighter quarters. The footprint difference might not seem significant on paper, but in a busy workshop, every square foot counts.

Third, some operators report that narrow-width gutter machines can handle certain materials with good results, though this always depends on the specific machine specifications and operator skill.

Practical Considerations Before Investing

For metal shops thinking about adding a narrow-width gutter roll former, there are practical aspects to weigh:

Material Handling: Ensure the machine can process the gauge and type of metal you commonly use

Production Volume: Assess whether the machine's output matches your typical job requirements

Tooling Options: Check what profile options are available and how easily they can be changed

Maintenance Needs: Understand any special care requirements compared to standard equipment

It's often helpful to see the machine in operation or talk with other shops that have made similar purchases. Real-world feedback can provide insights that specifications alone might not reveal.

The Place of Narrow Machines in Today's Market

While narrow-width gutter roll forming machines aren't replacing standard models, they're finding their place as useful specialty tools. For shops that regularly encounter projects requiring smaller profiles, having the right equipment can mean the difference between taking on a job or passing it by.

As with any equipment decision, the choice comes down to matching machine capabilities with the types of work a shop handles most often. For some operations, a narrow-width gutter machine might be just what's needed to expand their service offerings without requiring a complete overhaul of their existing setup.

The growing variety of available equipment gives metal fabricators more options than ever to find tools that fit their specific needs. Whether narrow-width gutter formers continue to gain ground will depend on how well they meet the practical demands of shops and the projects they take on.