Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:May 13, 2025 Visit:86 Source:Roll Forming Machine Factory

Despite advancements in metal forming technologies, roll forming machines remain the preferred choice for many industrial applications. Their continued dominance stems from a combination of efficiency, precision, and adaptability across various manufacturing sectors. This article explores the key reasons why roll forming machines maintain their mainstream status in metal forming.

1. High Production Efficiency

Roll forming machines excel in high-volume production, offering consistent output with minimal downtime. The continuous bending process allows for rapid fabrication of long metal strips with uniform cross-sections. Unlike stamping or pressing methods, roll forming operates at a steady pace, reducing bottlenecks in mass production environments.

2. Precision and Consistency

The incremental bending process in roll forming ensures tight tolerances and repeatable accuracy. Each set of rollers gradually shapes the metal, minimizing material stress and preventing deformations. This precision is critical in industries such as automotive, construction, and appliance manufacturing, where component uniformity is essential.

3. Material Versatility

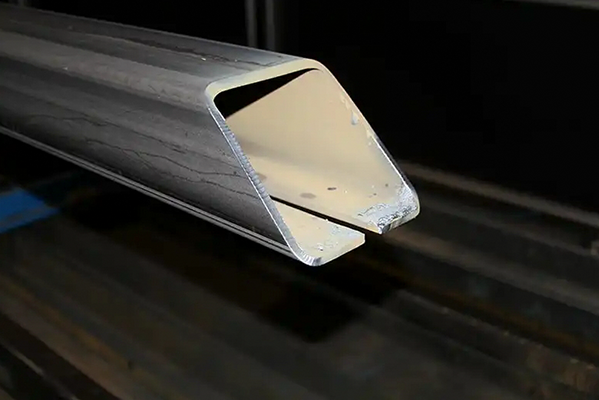

Roll forming accommodates a wide range of metals, including steel, aluminum, copper, and alloys. The process can handle varying thicknesses and material grades without requiring extensive retooling. This flexibility makes it suitable for diverse applications, from structural beams to intricate trim profiles.

4. Cost-Effectiveness for Long Runs

While initial setup costs may be higher than some alternative methods, roll forming becomes highly economical for large production runs. The reduced per-unit cost, combined with lower scrap rates due to efficient material usage, makes it a financially viable solution for manufacturers.

5. Integration with Secondary Processes

Modern roll forming lines seamlessly integrate with punching, cutting, and welding systems, allowing for in-line finishing operations. This integration reduces handling time and improves workflow efficiency, making roll forming a central component in automated production systems.

6. Durability and Low Maintenance

Roll forming machines are built for long-term operation with minimal maintenance requirements. The absence of high-impact forces (unlike stamping presses) reduces wear on tooling, extending equipment lifespan and lowering operational costs over time.

Conclusion

Roll forming machines continue to dominate metal forming due to their unmatched efficiency, precision, and adaptability. As manufacturing demands evolve, advancements in roll forming technology ensure its relevance in producing high-quality metal components across industries. Their ability to balance speed, accuracy, and cost-effectiveness solidifies their position as a cornerstone of modern metal fabrication.