Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:May 14, 2025 Visit:79 Source:Roll Forming Machine Factory

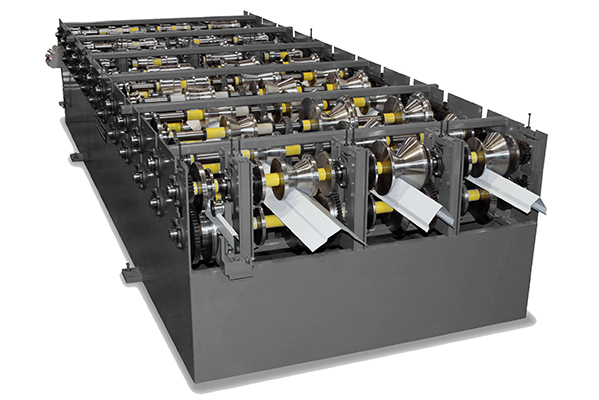

Gutter manufacturing has seen steady technological advances over the years, with roll forming systems emerging as a modern alternative to traditional gutter machines. However, many operators have been slow to make the switch. Let's examine some practical reasons why gutter roll forming machines haven't completely replaced traditional equipment in many shops.

Cost Considerations Play a Major Role

For small to mid-sized gutter operations, the initial investment in a gutter roll forming machine can be substantial compared to traditional equipment. Many established businesses already have working traditional machines that continue to meet their production needs. The cost-benefit analysis often doesn't justify replacing functional equipment that still produces quality gutters at acceptable speeds.

Training and Learning Curve Factors

Workers familiar with traditional gutter machines often require significant retraining to operate roll forming systems efficiently. The setup, operation, and maintenance procedures differ considerably between the two technologies. Some operators prefer sticking with equipment their teams already know well rather than facing potential productivity dips during the transition period.

Space Requirements and Shop Layouts

Gutter roll forming machines typically require more floor space than traditional gutter machines. Many existing shops would need to rearrange their production areas or expand their facilities to accommodate roll forming systems. For businesses operating in tight spaces or leased buildings, this physical constraint can be a significant barrier to adoption.

Production Volume Considerations

While gutter roll forming machines offer advantages for high-volume production, many regional gutter manufacturers don't operate at scales that would make the switch compelling. Traditional machines can adequately meet the production demands of many local and regional markets without the need for more advanced equipment.

Maintenance and Repair Considerations

Traditional gutter machines are often simpler in design with mechanical components that many shop technicians can service without specialized training. Roll forming systems may require more specialized knowledge for maintenance and repairs, potentially leading to longer downtime when issues arise and higher costs for service calls.

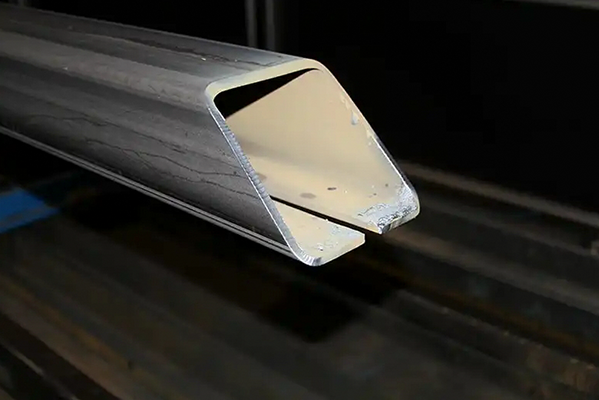

Material Handling Differences

The way materials feed into traditional gutter machines differs from roll forming systems. Some operators find their existing material handling processes work better with traditional equipment, and changing over would require modifying multiple aspects of their production workflow beyond just the gutter-making machine itself.

Market Demand for Customization

Certain niche markets still demand gutter profiles or customizations that traditional machines handle more readily than some roll forming systems. While modern gutter roll forming machines offer impressive flexibility, some operators find traditional equipment better suited to their specific product mix and customer requirements.

The Bottom Line for Gutter Manufacturers

The decision to upgrade equipment always involves careful consideration of costs, production needs, and return on investment. For many gutter manufacturers, traditional machines continue to represent a reliable, cost-effective solution that meets their business requirements. As technology advances and business needs evolve, we may see more operators gradually transitioning to gutter roll forming machines, but for now, both technologies have their place in the industry.

Operators considering the switch should carefully evaluate their specific production volumes, product mix, workforce capabilities, and growth plans when deciding between maintaining traditional equipment or investing in a gutter roll forming machine system.