Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Jun 20, 2025 Visit:80 Source:Roll Forming Machine Factory

Automation is becoming an essential part of modern railroad equipment production. As manufacturers aim to improve efficiency, consistency, and output, automated systems are playing a growing role in the way railroad components and machinery are produced. But how exactly is automation shaping this industry today?

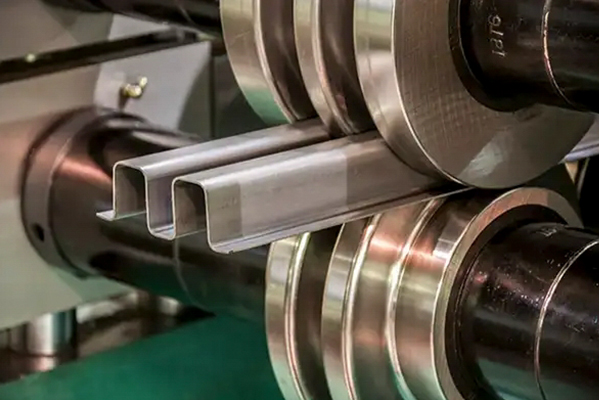

Streamlining Manufacturing Processes

One of the key benefits of automation in railroad equipment production is the ability to streamline complex manufacturing processes. Automated machines can perform tasks such as welding, cutting, assembling, and painting with precision and speed. This helps manufacturers shorten production cycles, reduce manual workload, and achieve stable product quality.

Improving Consistency and Accuracy

Railroad equipment often requires strict dimensional accuracy and high-quality assembly. Automated systems can maintain uniform standards throughout the production line, minimizing variations between parts. This consistency is critical for the performance and safety of railroad components, especially in large-scale manufacturing.

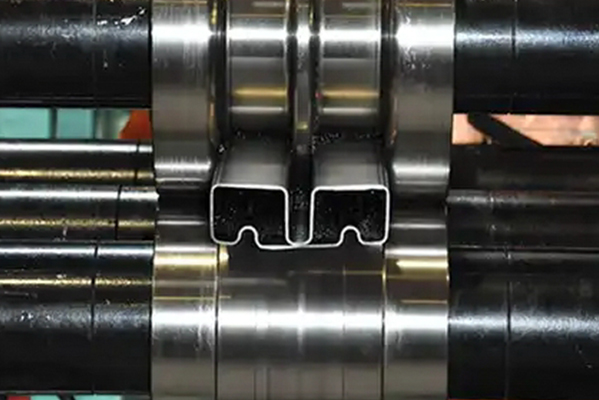

Supporting Complex Component Assembly

Some railroad equipment includes intricate assemblies that would be time-consuming to produce manually. Automation allows manufacturers to handle complex tasks with high repeatability. For example, robotic arms can assemble small, detailed parts quickly and with reduced error rates, improving production reliability.

Enhancing Quality Control

Modern production lines often include automated inspection systems that can detect defects early. Vision inspection tools, sensors, and testing machines can check the surface, dimensions, and strength of railroad components without slowing down the production process. This contributes to better product quality and helps manufacturers reduce waste.

Increasing Production Capacity

Automation enables higher production output without the need for significant increases in labor. With automated machinery operating at consistent speeds, manufacturers can meet growing market demands while maintaining delivery schedules. This is especially useful when fulfilling large orders for rail projects.

Reducing Human Error

By automating repetitive and labor-intensive tasks, the risk of human error is significantly reduced. This not only improves product accuracy but also enhances workplace safety, as automation can take over potentially hazardous processes such as heavy lifting, hot work, or chemical handling.

Supporting Flexible Production Lines

Modern automated systems can often be reprogrammed or adjusted to handle different types of railroad components. This flexibility allows manufacturers to quickly switch between product models or adapt to specific customer requirements without major equipment changes.

Conclusion

Automation plays an important role in modern railroad equipment production by improving efficiency, accuracy, and capacity while reducing manual errors and enhancing safety. As technology continues to advance, automation is expected to become even more integrated into the industry, helping manufacturers meet the growing demands of the rail sector with reliable, high-quality products.