Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Jun 20, 2025 Visit:80 Source:Roll Forming Machine Factory

Railroad components are often exposed to challenging environments, including heavy loads, high-speed operations, temperature fluctuations, and moisture. To maintain reliability and long service life, manufacturers must carefully design and produce components that can perform well under such demanding conditions. But how do railroad component manufacturers ensure durability in extreme situations?

Careful Material Selection

One of the primary ways manufacturers ensure durability is by selecting suitable materials. Railroad components such as wheels, axles, and fasteners must be able to resist stress, corrosion, and wear. Manufacturers commonly use specially engineered steels and treated alloys that provide strong mechanical properties and can withstand constant friction and impact.

Advanced Heat Treatment Processes

Heat treatment is a widely used technique to improve the hardness and toughness of metal parts. Through controlled heating and cooling processes, manufacturers can enhance the internal structure of railroad components, making them more resistant to cracking and fatigue, especially in environments with frequent temperature changes or mechanical stress.

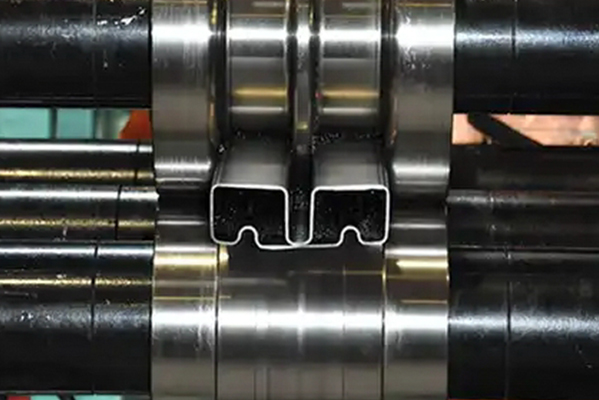

Precision Manufacturing and Quality Control

Railroad component manufacturers rely on precision machining to produce parts that meet strict dimensional tolerances. Accurate manufacturing helps ensure proper fitting and reduces the risk of component failure caused by misalignment or uneven pressure. Additionally, rigorous quality control inspections are performed at each stage of production to detect possible defects before the components are put into service.

Specialized Coatings and Surface Treatments

Surface treatments such as anti-corrosion coatings, plating, and lubrication layers play a key role in protecting components from harsh conditions. In areas where moisture, chemicals, or abrasive materials are present, these protective layers help prevent rust, reduce friction, and extend the usable life of railroad parts.

Fatigue and Stress Testing

To confirm the durability of their products, manufacturers conduct fatigue and stress tests that simulate real-world operating conditions. Components are exposed to repeated loading cycles, high-impact forces, and vibration to assess their long-term performance. These tests help manufacturers identify potential weak points and improve designs before large-scale production.

Custom Solutions for Regional Needs

Some railroad systems operate in environments with extreme cold, high heat, or coastal exposure. In response, manufacturers may develop customized components specifically designed to meet the unique demands of certain regions. This approach helps rail operators maintain reliable performance even in the most challenging locations.

Conclusion

Railroad component manufacturers ensure durability in extreme conditions through a combination of careful material selection, advanced heat treatment, precision manufacturing, protective surface treatments, and rigorous testing. These methods allow railroad components to maintain safety and functionality under heavy use and harsh environments. As the industry continues to evolve, manufacturers will likely keep refining these techniques to meet the growing demands of modern rail operations.