Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Jul 20, 2025 Visit:58 Source:Roll Forming Machine Factory

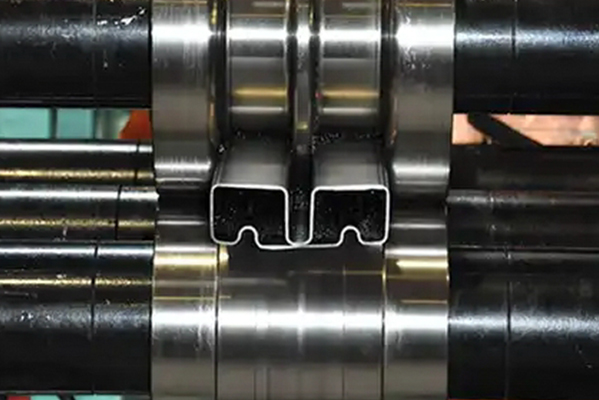

Custom roll forming machines have become essential in modern automotive manufacturing, offering precision, efficiency, and versatility in producing complex metal components. These machines shape metal sheets into desired profiles through a continuous bending process, ensuring consistent quality and reducing material waste. As the automotive industry evolves with demands for lighter, stronger, and more cost-effective parts, custom roll forming plays a crucial role in meeting these requirements.

Key Benefits of Custom Roll Forming in Automotive Production

1. High Precision and Consistency

Custom roll forming machines produce parts with tight tolerances, ensuring uniformity across large production runs. This precision is vital for automotive components that require exact dimensions, such as structural reinforcements, chassis parts, and trim elements.

2. Cost Efficiency

By minimizing material waste and reducing secondary operations, roll forming lowers production costs. The process also allows for high-speed manufacturing, increasing output while maintaining quality.

3. Design Flexibility

Automakers can create complex profiles tailored to specific vehicle models. Custom roll forming accommodates various materials, including high-strength steel and aluminum, supporting lightweight vehicle designs without compromising durability.

4. Enhanced Strength and Durability

The cold-forming process used in roll forming improves the mechanical properties of metal parts, making them stronger and more resistant to fatigue compared to traditional fabrication methods.

5. Streamlined Production Integration

Roll forming lines can be integrated with other manufacturing processes, such as punching, welding, and cutting, allowing for seamless production of finished components ready for assembly.

Applications in Automotive Manufacturing

Structural Components: Door beams, bumpers, and roof rails benefit from roll forming’s strength and precision.

Exterior Trim: Custom profiles for window seals, beltline moldings, and side trims are efficiently produced.

Chassis and Frame Parts: Roll-formed sections contribute to vehicle rigidity and crashworthiness.

Battery Enclosures for Electric Vehicles (EVs): The growing EV market relies on roll forming for lightweight yet durable battery housings.

Conclusion

Custom roll forming machines are indispensable in modern automotive manufacturing, enabling the production of high-quality, cost-effective, and lightweight components. As vehicle designs continue to advance, the adaptability and efficiency of roll forming will remain a key factor in meeting industry demands. Manufacturers leveraging this technology gain a competitive edge by improving production speed, reducing costs, and enhancing part performance.