Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Jul 20, 2025 Visit:70 Source:Roll Forming Machine Factory

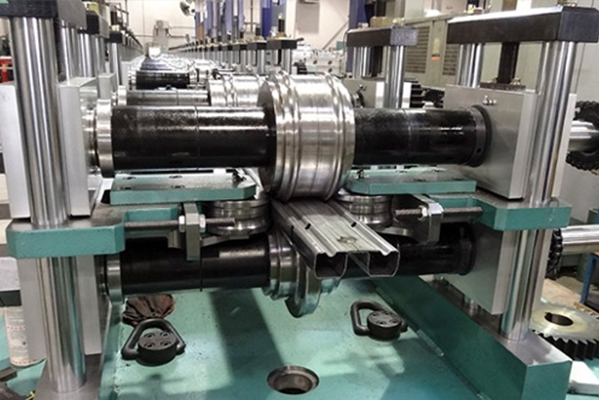

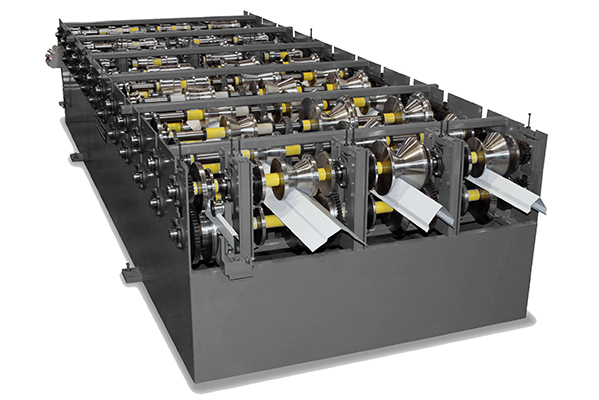

Custom roll forming machines are essential in manufacturing precise metal profiles for various industries, including automotive, construction, and aerospace. The integration of advanced control systems has significantly improved their performance, enabling higher precision, efficiency, and adaptability. This article explores how modern control technologies optimize roll forming operations.

1. Improved Precision and Consistency

Advanced control systems utilize high-resolution sensors and real-time feedback mechanisms to ensure consistent material shaping. Closed-loop control adjusts roll positions dynamically, compensating for material variations and tool wear. This reduces dimensional deviations and minimizes scrap rates.

2. Enhanced Speed and Productivity

Automated control systems optimize forming speeds while maintaining accuracy. Programmable logic controllers (PLCs) and servo-driven adjustments allow rapid transitions between different profiles, reducing downtime. Adaptive algorithms also prevent overloading, ensuring smooth operation at optimal production rates.

3. Flexibility in Customization

Modern control interfaces support quick programming for complex profiles. Operators can store and recall preset configurations, facilitating seamless transitions between different product designs. This adaptability is crucial for manufacturers handling small-batch or highly specialized orders.

4. Reduced Operational Errors

Automated diagnostics and error detection systems minimize human intervention. Alerts for misalignments, material jams, or excessive force enable proactive maintenance, reducing unplanned stoppages. Predictive analytics further enhance reliability by identifying potential issues before they escalate.

5. Integration with Smart Manufacturing

Advanced controls enable seamless connectivity with factory automation systems. Data from roll forming machines can be integrated into enterprise resource planning (ERP) systems for better production tracking and inventory management. This connectivity supports just-in-time manufacturing and improves overall workflow efficiency.

Conclusion

The adoption of advanced control systems in custom roll forming machines has transformed their performance, offering greater precision, efficiency, and operational reliability. As technology continues to evolve, further enhancements in automation and data integration will drive even higher levels of productivity in metal forming applications.