Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Jul 18, 2025 Visit:65 Source:Roll Forming Machine Factory

Roll forming machines have become essential equipment in modern construction projects, offering efficiency, precision, and versatility in metal fabrication. These machines shape metal coils into desired profiles through a continuous bending process, producing consistent and high-quality components used in various structural and architectural applications.

Precision and Consistency in Metal Fabrication

One of the key advantages of roll forming machines is their ability to produce uniform metal sections with tight tolerances. Unlike traditional metalworking methods, roll forming ensures consistent dimensions across long production runs, reducing material waste and improving structural integrity. This precision is particularly valuable in construction, where standardized components are required for framing, roofing, and cladding systems.

Efficiency in Large-Scale Production

Construction projects often demand high volumes of metal parts, such as steel studs, purlins, and decking. Roll forming machines excel in mass production, enabling rapid fabrication without sacrificing quality. The automated process minimizes manual labor, reducing production time and costs while maintaining high output levels. This efficiency helps meet tight project deadlines and supports just-in-time manufacturing for construction sites.

Versatility in Material and Design Applications

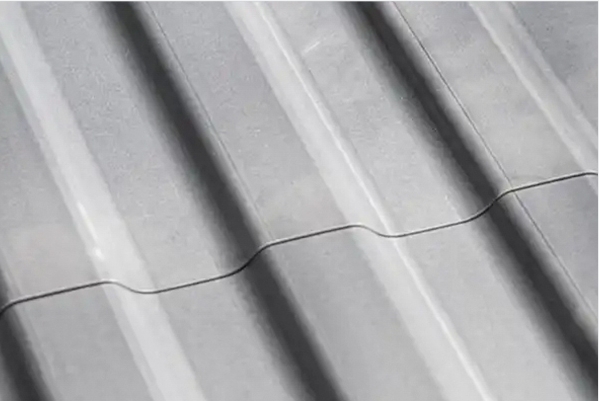

Modern roll forming machines can process a variety of metals, including steel, aluminum, and galvanized coatings, making them suitable for diverse construction needs. They can produce complex profiles, such as C-sections, Z-shapes, and custom trim pieces, allowing architects and engineers to incorporate specialized designs into buildings. Additionally, roll-formed components are lightweight yet durable, contributing to structural stability without excessive weight.

Integration with Building Systems

Roll-formed metal parts are widely used in:

Structural Framing: Light-gauge steel studs and tracks for walls and partitions.

Roofing and Wall Panels: Corrugated and trapezoidal sheets for weather-resistant enclosures.

Floor and Ceiling Systems: Metal decking and suspension components for support.

HVAC and Electrical Enclosures: Ductwork and cable management solutions.

By providing standardized yet customizable solutions, roll forming machines support modular construction techniques, enhancing project scalability and repeatability.

Conclusion

Roll forming machines play a crucial role in modern construction by delivering precise, high-volume metal components efficiently. Their ability to produce consistent profiles from various materials makes them indispensable for structural and architectural applications. As construction methods continue to evolve, roll forming technology remains a reliable solution for meeting industry demands in quality, speed, and adaptability.