Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Jul 18, 2025 Visit:73 Source:Roll Forming Machine Factory

Roll forming machines have become an important part of modern manufacturing processes across various industries. This article examines whether these machines are appropriate for operations requiring large-scale production output, focusing on their capabilities, advantages, and considerations for implementation.

Understanding Roll Forming Technology

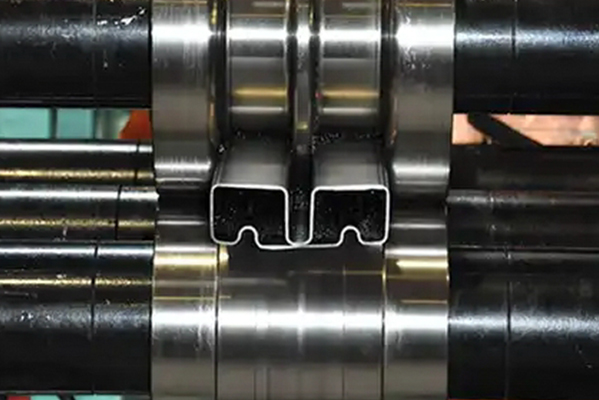

Roll forming is a continuous bending operation where long strips of metal, typically coiled steel, pass through sets of rolls mounted on consecutive stands. Each set performs incremental parts of the bend until the desired cross-section profile is achieved. This process differs from other metal forming methods in its approach to shaping materials.

Production Capacity of Roll Forming Systems

Modern roll forming equipment can achieve notable production speeds, often ranging between 30 to 600 feet per minute depending on material type and profile complexity. Many systems operate continuously, only requiring periodic stops for coil changes or maintenance procedures. This uninterrupted operation contributes to steady output levels.

Advantages for Large-Scale Manufacturing

Several characteristics make roll forming machines appropriate for substantial production volumes:

Consistent Output: Once properly set up, these machines can maintain uniform product quality over extended run times

Material Efficiency: The process generates minimal scrap compared to alternative methods

Labor Requirements: Automated systems reduce the need for extensive manual intervention

Flexibility: Quick changeovers between similar profiles allow for production variety

Economic Considerations

For businesses evaluating roll forming for high-volume applications, several financial factors should be examined:

Initial equipment investment costs versus long-term operational savings

Maintenance requirements and associated expenses

Training needs for personnel operating the machinery

Potential reduction in per-unit production costs at higher volumes

Technical Considerations

Implementing roll forming for mass production requires attention to:

Material specifications and tolerances

Tooling design and maintenance schedules

Quality control measures throughout the production process

Integration with other manufacturing systems

Industry Applications

Roll forming serves numerous sectors requiring large quantities of formed metal products:

Construction components

Automotive parts

Appliance manufacturing

Storage systems

Electrical enclosures

Conclusion

Roll forming machines can be effectively implemented in high-volume production environments when properly selected and maintained. Their continuous operation capability, consistent output quality, and efficient material usage make them a practical option for manufacturers requiring substantial production quantities. Businesses considering this technology should evaluate their specific production needs, material requirements, and long-term operational goals to determine if roll forming represents the optimal solution for their manufacturing processes.