Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Aug 11, 2025 Visit:111 Source:Roll Forming Machine Factory

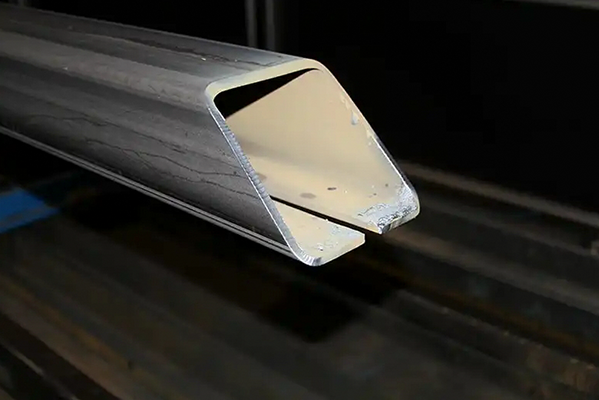

In metal forming, equipment durability plays a key role in maintaining consistent production and long-term operational value. Heavy gauge rollformers are built to handle demanding workloads, making them a dependable choice for producing thick, high-strength metal profiles across various industries.

1. Robust Machine Construction

Heavy gauge rollformers feature reinforced frames and components that can withstand the stress of shaping thicker materials. This solid build ensures stability during operation, which directly contributes to product accuracy and machine longevity.

2. Precision Under High Load

The forming process for heavy gauge metals requires sustained force and exact alignment. Advanced rollformers use precision-engineered stands, shafts, and tooling to maintain tight tolerances, even under high load conditions.

3. Adaptability to Diverse Applications

These machines are versatile enough to produce a wide range of profiles, from structural beams to industrial enclosures. The ability to accommodate different tooling setups without compromising performance makes them a practical solution for manufacturers with varied product lines.

4. Reduced Downtime Through Wear-Resistant Components

Key machine parts such as rollers, bearings, and drive systems are designed with wear-resistant materials and treatments. This minimizes maintenance frequency and supports longer production runs without interruptions.

5. Consistent Output Over Time

The durability of heavy gauge rollformers translates into sustained production quality. Even after extended use, these machines can continue delivering accurate, repeatable results, reducing the risk of defects and rework.

Conclusion

Heavy gauge rollformers combine strength, precision, and reliability to provide a durable solution for metal forming. Their ability to maintain consistent performance under demanding conditions makes them a valuable investment for manufacturers aiming for long-term productivity and product quality.