Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Aug 11, 2025 Visit:79 Source:Roll Forming Machine Factory

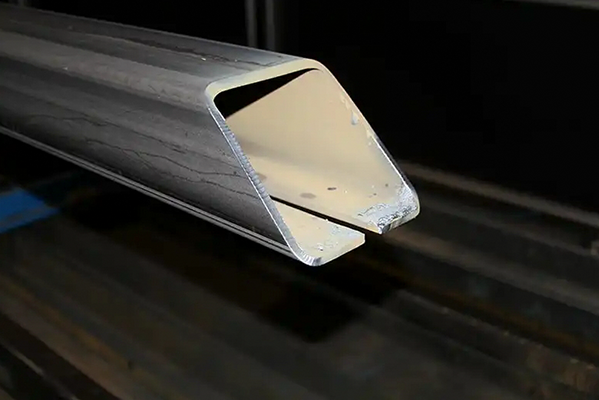

In metal forming and fabrication, the ability to work with thicker materials can significantly influence production efficiency and product range. Equipment capable of handling material up to 0.500 inches thick provides manufacturers with greater versatility, structural strength, and operational flexibility.

1. Expanded Product Possibilities

The capability to process 0.500" thick material allows manufacturers to produce a wider variety of heavy-duty components. This includes structural supports, industrial enclosures, and large-scale assemblies that require high load-bearing capacity.

2. Enhanced Structural Integrity

Thicker material often means stronger end products. When manufacturing parts that must endure substantial mechanical stress, the ability to work with 0.500" thickness ensures durability and long-term performance.

3. Reduced Multi-Piece Assemblies

With the ability to use thicker material, some designs can be produced as single, solid components rather than multiple joined parts. This reduces welding or fastening steps, improves precision, and shortens assembly time.

4. Improved Efficiency in Heavy-Duty Applications

Processing thicker material in-house eliminates the need to outsource certain jobs, helping streamline production schedules and maintain tighter control over lead times.

5. Compatibility with Specialized Industries

Industries such as construction, transportation, and heavy equipment manufacturing often require components made from thicker metals. Having 0.500" capability positions manufacturers to serve these sectors without additional equipment investments.

Conclusion

The ability to handle 0.500" material thickness expands manufacturing capabilities, increases product strength, and improves production flexibility. For companies serving heavy-duty markets, this capability can be a strategic advantage in meeting diverse customer requirements.