Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Jun 08, 2025 Visit:68 Source:Roll Forming Machine Factory

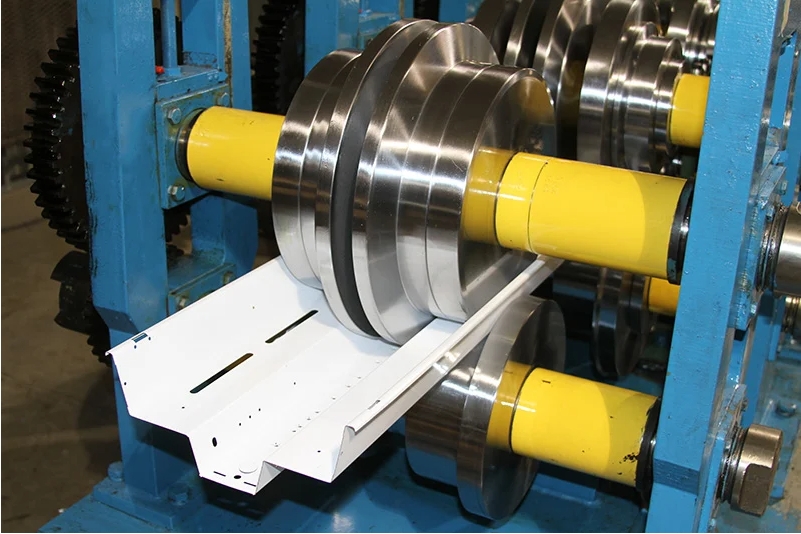

The construction industry has seen increasing adoption of roll forming equipment in recent years. This specialized machinery shapes metal coils into precise profiles through a series of roller dies, offering distinct advantages for modern building projects. Several factors contribute to this rising demand across global construction markets.

Efficiency in Material Usage and Production

Roll forming equipment allows for optimized material utilization, reducing waste compared to traditional metal shaping methods. The continuous process enables manufacturers to create long lengths of formed metal without joints or seams. This efficiency translates to cost savings for construction projects while maintaining structural integrity of building components.

Precision and Consistency in Manufacturing

Modern roll forming machines produce components with tight tolerances and uniform quality. This level of precision meets the exacting standards required in contemporary construction projects. The repeatability of the process ensures identical profiles across large production runs, facilitating easier assembly and installation on job sites.

Versatility in Design Applications

Advancements in roll forming technology have expanded the range of possible profiles and materials. Construction firms can now specify custom shapes for various applications while maintaining production efficiency. This flexibility supports architectural innovation while keeping manufacturing costs manageable.

Economic Advantages for Large-Scale Projects

For projects requiring substantial quantities of metal components, roll forming offers economic benefits through reduced labor requirements and faster production times. The automated nature of modern equipment lowers per-unit costs as production volume increases, making it particularly suitable for large construction developments.

Durability and Performance Characteristics

Components produced through roll forming demonstrate reliable performance in construction applications. The work-hardening effect of the forming process can enhance certain material properties, contributing to the longevity of building systems. This durability factor influences many purchasing decisions in the construction sector.

Adaptability to Industry Requirements

Roll forming equipment continues to evolve to meet changing construction needs. Manufacturers have developed systems capable of handling various coatings and pre-finished materials while maintaining production quality. This adaptability ensures the technology remains relevant as construction methods and material preferences develop.

The construction industry's growing preference for roll forming equipment stems from its combination of production efficiency, quality output, and economic benefits. As building projects become more complex and cost-conscious, these machines provide solutions that balance performance with practicality. Ongoing technological improvements suggest this trend will continue as the equipment addresses an expanding range of construction applications.