Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Jul 17, 2025 Visit:67 Source:Roll Forming Machine Factory

Roll forming machine technology continues to evolve, offering manufacturers improved efficiency, precision, and versatility. Recent advancements focus on automation, material handling, and adaptive control systems, enhancing production capabilities across various industries. Below are some of the most notable innovations in roll forming technology.

1. Advanced Automation and Smart Controls

Modern roll forming machines increasingly incorporate automation to streamline production. Features such as programmable logic controllers (PLCs) and human-machine interfaces (HMIs) allow operators to adjust parameters easily. Some systems now integrate artificial intelligence (AI) to optimize forming processes in real time, reducing material waste and improving consistency.

2. High-Speed Roll Forming Systems

Newer machines are designed for faster production speeds without compromising accuracy. Improved servo-driven systems and precision gearboxes enable high-speed forming while maintaining tight tolerances. These enhancements are particularly beneficial for industries requiring large-volume output, such as construction and automotive manufacturing.

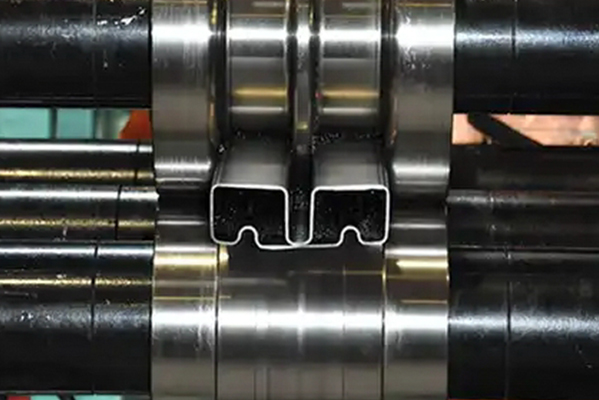

3. Modular and Flexible Tooling Designs

Manufacturers now offer modular roll forming systems that allow quick tooling changes. This flexibility reduces downtime when switching between different profiles or materials. Some machines feature adjustable forming stands, enabling rapid reconfiguration for custom or complex shapes.

4. Improved Material Handling and Feeding Systems

Innovations in material feeding ensure smoother coil loading and reduced setup time. Advanced decoilers and straightening systems enhance material flow, minimizing jams and improving overall efficiency. Laser-guided alignment systems further enhance precision during the forming process.

5. Enhanced Quality Monitoring and Inspection

Real-time monitoring systems now detect defects early in production. Vision-based inspection tools and laser measurement devices ensure dimensional accuracy, reducing scrap rates. Some machines also include predictive maintenance features, alerting operators to potential issues before they cause downtime.

6. Energy-Efficient Drive Systems

While avoiding specific terminology, it's worth noting that modern roll forming machines incorporate optimized drive mechanisms that reduce operational costs. Regenerative braking systems and energy-efficient motors contribute to more sustainable production without compromising performance.

7. Integration with Industry 4.0 Technologies

Roll forming machines are increasingly connected to smart factory networks. IoT-enabled devices collect production data for analytics, helping manufacturers optimize workflows. Cloud-based monitoring allows remote diagnostics and performance tracking, improving overall equipment effectiveness (OEE).

Conclusion

The latest advancements in roll forming machine technology focus on automation, speed, flexibility, and precision. With smarter controls, modular designs, and enhanced monitoring, manufacturers can achieve higher productivity and better-quality output. As Industry 4.0 integration expands, roll forming systems will continue to evolve, offering even greater efficiency and adaptability for modern production needs.