Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Jul 17, 2025 Visit:54 Source:Roll Forming Machine Factory

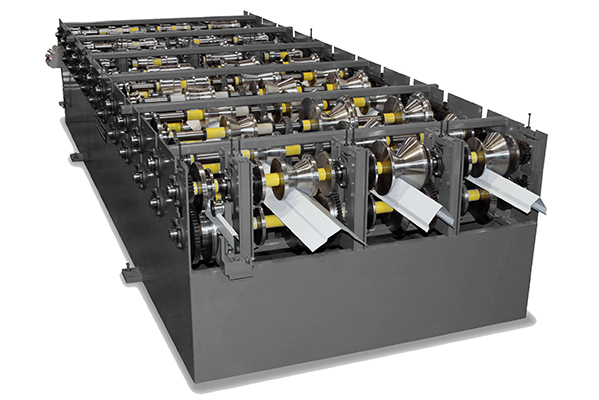

Roll forming machines are versatile manufacturing systems designed to shape metal materials into desired cross-sectional profiles. These machines work by progressively bending long strips of metal through a series of roller dies without changing the material thickness. The process is continuous and highly efficient for producing consistent, high-quality metal components.

Metal Material Compatibility

Roll forming machines demonstrate considerable flexibility in working with various metal materials. The most commonly processed metals include:

Carbon steel: A widely used material due to its strength and cost-effectiveness

Stainless steel: Selected for applications requiring corrosion resistance

Aluminum: Chosen for its lightweight properties and formability

Galvanized steel: Used when additional protection against rust is needed

Copper and brass: Occasionally processed for specific electrical or decorative applications

Factors Affecting Material Handling Capability

Several technical considerations determine a roll forming machine's ability to work with different metals:

Material thickness: Machines are typically designed to handle specific thickness ranges

Tensile strength: Higher strength materials may require more powerful equipment

Ductility: Affects how easily the material can be formed without cracking

Surface characteristics: Some coatings or finishes may require special handling

Machine Adjustments for Different Materials

Operators can modify roll forming machines to accommodate various metals through:

Tooling changes to match material properties

Speed adjustments to account for material hardness

Pressure regulation to ensure proper forming without deformation

Guide modifications to maintain material alignment during processing

Application Considerations

When selecting materials for roll forming processes, manufacturers consider:

The intended use of the final product

Environmental conditions the product will face

Required mechanical properties of the finished component

Cost-effectiveness of the material choice

Conclusion

Modern roll forming machines offer substantial capability to process a range of metal materials. Their adaptability makes them valuable tools in metal fabrication, allowing manufacturers to produce diverse products from different metals while maintaining efficiency and quality standards. The specific capabilities depend on machine design and configuration, with most systems able to handle multiple metal types with appropriate adjustments.