Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:May 20, 2025 Visit:72 Source:Roll Forming Machine Factory

Door angle roll forming lines represent a significant advancement in metal fabrication technology, offering manufacturers a reliable method for producing consistent, high-quality door angles. These specialized systems have become increasingly important in modern manufacturing environments where precision and efficiency are paramount.

How Door Angle Roll Forming Lines Work

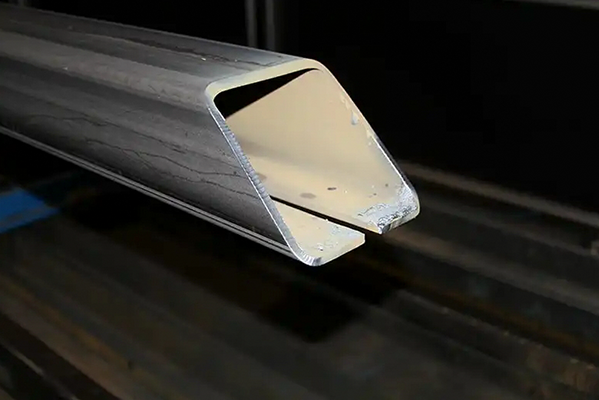

A door angle roll forming line is a continuous bending operation where a long strip of metal is passed through sets of rollers that progressively shape the material into the desired cross-section. Unlike traditional methods that might require multiple steps, these systems complete the forming process in a single pass, significantly reducing handling time between operations.

The process begins with coil loading, where the raw metal material is fed into the system. The metal then passes through a series of precisely engineered roll stations, each contributing to the final angle shape. Modern lines often incorporate computerized controls that monitor and adjust the forming process in real-time.

Key Efficiency Benefits in Metal Fabrication

Door angle roll forming lines offer several advantages that contribute to improved manufacturing efficiency:

Continuous Production Capability: These systems can operate continuously with minimal downtime between production runs, allowing for higher output volumes compared to batch processing methods.

Reduced Material Waste: The precision of roll forming minimizes material waste by ensuring accurate bends and consistent product dimensions throughout the production run.

Lower Labor Requirements: Automated door angle roll forming lines require fewer operators than traditional fabrication methods, reducing labor costs while maintaining high production rates.

Consistent Product Quality: The automated nature of the process eliminates variations that might occur with manual fabrication methods, ensuring every piece meets exact specifications.

Technical Advantages Over Traditional Methods

When compared to conventional metal bending techniques, door angle roll forming lines demonstrate superior performance in several technical aspects:

Precision Engineering: Modern lines can maintain tight tolerances, often within fractions of a millimeter, which is crucial for door frame components that must fit together perfectly.

Speed of Operation: High-speed roll forming can produce finished angles at rates significantly faster than manual or semi-automated methods.

Flexibility in Production: Many systems allow for quick changeovers between different angle sizes or profiles, making them suitable for varied production needs.

Operational Considerations for Implementation

For manufacturers considering integrating door angle roll forming lines into their operations, several factors should be evaluated:

Initial Investment: While the upfront cost may be higher than traditional equipment, the long-term efficiency gains often justify the expenditure.

Space Requirements: These systems typically require linear space for the forming line and associated equipment, which may necessitate facility adjustments.

Maintenance Needs: Regular maintenance is essential to keep the precision components operating at peak efficiency, though modern systems are designed for reliability.

Industry Applications Beyond Door Manufacturing

While primarily used for door angle production, these roll forming lines have applications in various metal fabrication sectors:

Window frame components

Structural framing elements

Architectural metalwork

Industrial equipment framing

The versatility of the technology allows manufacturers to adapt the basic roll forming principles to different product requirements.

Future Developments in Roll Forming Technology

The ongoing evolution of door angle roll forming technology continues to push efficiency boundaries. Emerging trends include:

Enhanced integration with digital control systems

Improved quick-change mechanisms for faster product transitions

Advanced sensor technology for real-time quality monitoring

Energy-efficient drive systems that maintain performance while reducing operating costs

Conclusion

Door angle roll forming lines have proven their value in metal fabrication by delivering consistent quality while improving production efficiency. For manufacturers looking to enhance their operational capabilities, these systems offer a compelling solution that balances precision, speed, and reliability. As the technology continues to advance, its role in modern metal fabrication is likely to expand further, solidifying its position as a preferred method for angle production.