Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Jun 22, 2025 Visit:69 Source:Roll Forming Machine Factory

The automotive industry is in a constant state of transformation, driven by demands for improved performance, vehicle integrity, and efficient production. In this evolving landscape, roll forming technology is gaining significant traction, with more automakers incorporating it into their manufacturing processes. This shift is due to a compelling combination of advantages that roll forming offers over other metal-forming techniques.

One of the primary drivers is cost-efficiency. Roll forming is a continuous process that can convert coiled metal strips into finished profiles with remarkable speed and minimal material waste. Unlike stamping, which often generates significant scrap, roll forming's near-net-shape production minimizes excess material, leading to substantial savings on raw material costs. Furthermore, the tooling costs for roll forming are typically lower than those for complex stamping dies, especially for long, intricate parts, making it a financially attractive option for high-volume production.

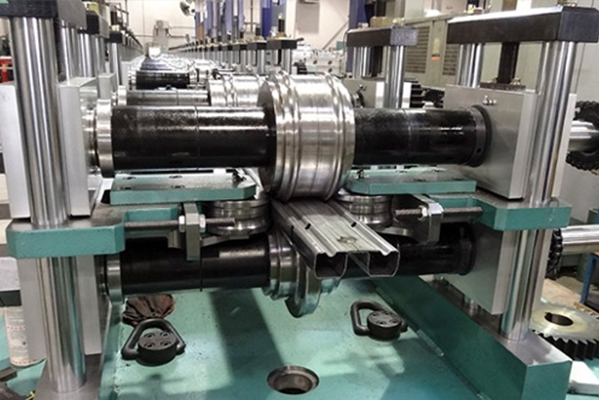

Precision and consistency are also major factors. Roll forming gradually shapes the metal through a series of rollers, allowing for very tight tolerances and consistent part dimensions across entire production runs. This precision is critical for automotive components that must fit together perfectly in automated assembly lines, contributing to overall vehicle quality and reducing potential rework. The controlled nature of the process also helps maintain the structural integrity of the material, which is crucial for parts that contribute to vehicle safety.

The ability to process advanced, high-strength materials is another key advantage. As automakers strive for lighter vehicles to enhance performance, they are increasingly turning to advanced high-strength steels (AHSS) and aluminum alloys. Roll forming is particularly adept at shaping these materials without compromising their enhanced properties. The gradual bending process is less aggressive than other methods, reducing the risk of material thinning, cracking, or other defects that can occur with high-strength metals. This capability enables the production of robust yet lightweight components, directly supporting modern vehicle design objectives.

Moreover, roll forming offers design flexibility. It can create a wide array of complex cross-sectional shapes and custom profiles that might be challenging or impossible to achieve with other methods. This allows designers to optimize component geometries for specific functional requirements, whether for structural support, aesthetic trim, or intricate internal channels. The versatility extends to integrating features like holes, notches, and even welding directly into the production line, further streamlining manufacturing.

Finally, the high production speed and automation potential of roll forming make it ideal for the automotive industry's mass production demands. Roll forming lines can operate at significant speeds, efficiently producing long lengths of profiles. The process is also highly amenable to automation, reducing reliance on manual labor and increasing throughput. The integration of advanced control systems and in-line operations means that complex parts can be produced from raw coil to finished component in a single, continuous process.

In essence, automakers are embracing roll forming technology because it offers a powerful combination of cost savings, precision, material versatility, design freedom, and high-volume production capabilities, all of which are essential for staying competitive in today's dynamic automotive market.