Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:May 19, 2025 Visit:79 Source:Roll Forming Machine Factory

The Lighting Industry is continuously evolving, with manufacturers seeking efficient and cost-effective production methods. One technology that has gained significant traction is the roll forming machine, which offers numerous advantages for producing lighting components. This article explores why more lighting manufacturers are turning to roll forming technology and how it benefits their operations.

The Growing Role of Roll Forming in the Lighting Industry

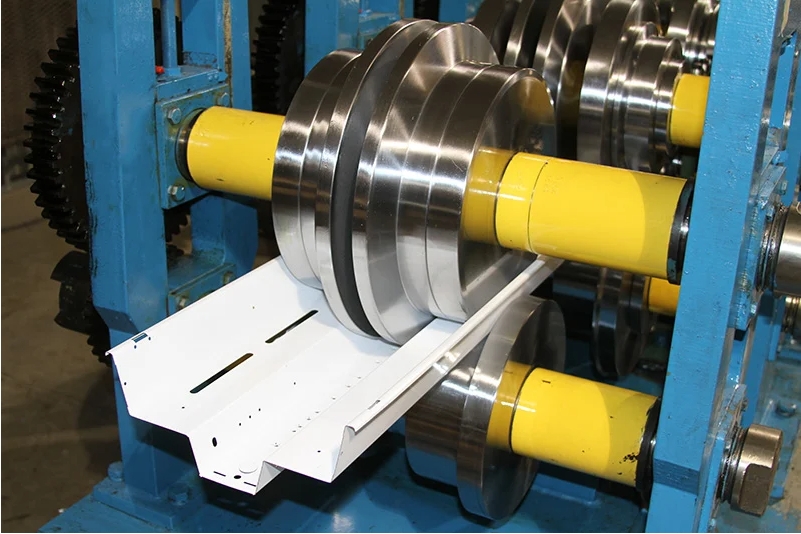

Roll forming is a metal forming process that shapes long strips of metal into desired profiles by passing them through a series of rollers. In the Lighting Industry, this method is increasingly used to create precise and consistent components such as:

Light fixture housings

Reflectors

Mounting brackets

Channel systems for LED lighting

The ability to produce complex shapes with tight tolerances makes roll forming machines ideal for lighting manufacturers looking to enhance product quality while reducing waste.

Key Benefits of Roll Forming for Lighting Manufacturers

1. High Precision and Consistency

Roll forming ensures uniform dimensions across large production runs, which is crucial for lighting components that require exact specifications. This consistency reduces assembly issues and improves overall product reliability.

2. Cost Efficiency

Compared to traditional stamping or extrusion methods, roll forming minimizes material waste and reduces labor costs. The process allows for high-speed production, making it a cost-effective solution for large-scale manufacturing.

3. Flexibility in Design

Lighting manufacturers can easily customize profiles to meet specific design requirements. A Lighting Industry roll forming machine can be adjusted to produce different shapes and sizes without requiring extensive tooling changes.

4. Durability and Strength

Roll-formed metal parts exhibit excellent structural integrity, ensuring that lighting fixtures are robust and long-lasting. This is particularly important for industrial and commercial lighting applications.

5. Scalability for Mass Production

With the ability to run continuously, roll forming is well-suited for high-volume production. Lighting manufacturers can meet market demands efficiently while maintaining quality standards.

Conclusion

As the Lighting Industry continues to advance, the adoption of roll forming machines is becoming more widespread due to their precision, efficiency, and versatility. Manufacturers leveraging this technology can achieve better product consistency, lower production costs, and faster turnaround times—key factors in staying competitive.

By integrating roll forming into their processes, lighting companies can enhance their manufacturing capabilities and deliver high-quality products that meet industry standards. This shift underscores the growing importance of advanced metal forming techniques in modern lighting production.