Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:May 13, 2025 Visit:80 Source:Roll Forming Machine Factory

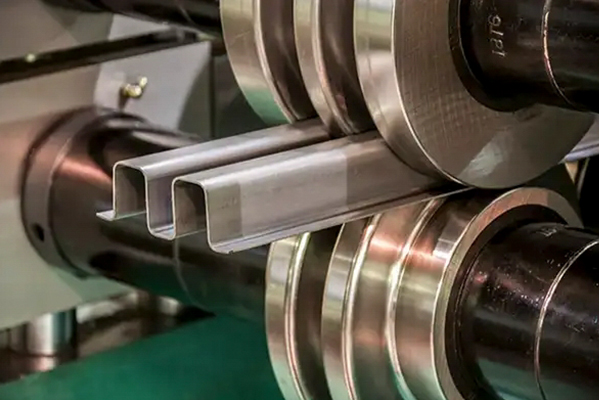

In recent years, roll forming machines have gained increasing attention in the manufacturing industry. Their ability to produce consistent, high-quality metal components with efficiency has made them a preferred choice for many manufacturers. This article explores the key reasons behind their rising prominence and how they contribute to modern production processes.

Precision and Consistency in Production

One of the primary advantages of roll forming machines is their ability to maintain tight tolerances across long production runs. Unlike other metal-forming methods, roll forming progressively shapes metal strips into desired profiles with minimal variation. This ensures uniformity in parts, reducing the need for secondary adjustments and improving overall product quality.

Cost-Effective Manufacturing

Roll forming machines offer economic benefits by minimizing material waste and reducing labor costs. Since the process uses coiled metal strips, scrap generation is significantly lower compared to traditional cutting and stamping methods. Additionally, the automation capabilities of modern roll forming systems decrease reliance on manual labor, leading to lower operational expenses over time.

High-Speed Production Capabilities

The efficiency of roll forming machines allows for rapid production rates, making them ideal for large-volume orders. Unlike slower forming techniques, roll forming can produce complex profiles at high speeds without sacrificing accuracy. This makes it a preferred solution for industries requiring mass production of metal components, such as automotive, construction, and appliance manufacturing.

Flexibility in Material and Design

Modern roll forming machines can process a variety of metals, including steel, aluminum, and copper, accommodating different industry needs. Additionally, advancements in machine design allow for quick tooling changes, enabling manufacturers to switch between product profiles with minimal downtime. This adaptability makes roll forming a versatile option for custom and standardized parts alike.

Reduced Secondary Operations

Since roll forming produces finished or near-finished parts, the need for additional machining or finishing steps is often eliminated. This streamlines the production process, shortening lead times and improving workflow efficiency. Manufacturers benefit from faster turnaround times while maintaining high product standards.

Conclusion

Roll forming machines continue to gain traction in the manufacturing sector due to their precision, cost efficiency, speed, and adaptability. As industries seek more reliable and economical production methods, roll forming stands out as a proven solution for high-quality metal component fabrication. Their ability to meet diverse manufacturing demands ensures their continued relevance in an evolving industrial landscape.