Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Jul 19, 2025 Visit:77 Source:Roll Forming Machine Factory

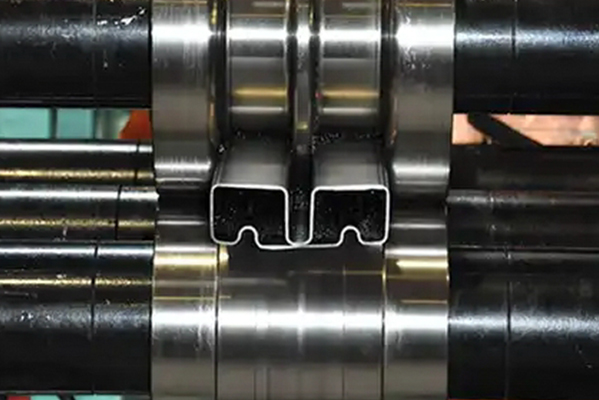

Custom roll forming machines have become essential tools for precision metal fabrication across multiple sectors. These specialized machines shape metal coils into continuous profiles with consistent cross-sections through a series of rollers, offering advantages in efficiency, accuracy, and material conservation. Several industries now rely on this technology for their production needs.

Construction and Architectural Applications

The building sector extensively uses roll formed products for structural components and decorative elements. Metal framing systems, roof and wall panels, gutters, and downspouts benefit from the dimensional accuracy and repeatability of custom roll forming. The technology allows for creating complex profiles that meet specific architectural requirements while maintaining structural integrity.

Automotive Manufacturing

Vehicle producers incorporate roll formed parts in various applications, including chassis components, seat frames, bumper reinforcements, and door beams. The automotive industry values this process for its ability to produce lightweight yet strong parts with tight tolerances, contributing to vehicle performance and safety standards.

Appliance Production

Home and commercial appliance manufacturers utilize roll forming for producing durable and precisely shaped metal parts. Refrigerator cabinets, oven components, washing machine drums, and air conditioning housings often originate from custom roll forming lines designed for specific product requirements.

Electronics and Electrical Equipment

The electronics industry employs roll formed parts in equipment enclosures, server racks, and electrical conduits. The precision of modern roll forming machines ensures proper fit and functionality for sensitive electronic components while providing necessary protection and heat dissipation properties.

Transportation and Logistics

Railway, aerospace, and shipping container manufacturers use roll formed components for structural elements, interior panels, and specialized cargo systems. The transportation sector benefits from the combination of strength and weight efficiency that roll formed metal parts provide.

Industrial Equipment Manufacturing

Machinery producers rely on roll formed parts for frames, guards, covers, and functional components. The ability to create custom profiles with consistent quality makes roll forming particularly valuable for industrial equipment that demands reliability and precise specifications.

The adoption of custom roll forming technology continues to expand as industries recognize its advantages for producing high-quality metal components with efficient material usage and consistent results. Manufacturers across these sectors invest in specialized roll forming equipment to maintain competitive production capabilities while meeting their specific design and performance requirements.