Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:May 07, 2025 Visit:88 Source:Roll Forming Machine Factory

When it comes to storing large quantities of grain, cement, or other bulk materials, steel silos are a go-to solution for many industries. But have you ever wondered how these massive storage structures are made efficiently and cost-effectively? That’s where steel silo roll forming machines come into play. These machines are the backbone of modern silo production, ensuring durability, precision, and scalability in storage solutions.

How Steel Silo Roll Forming Machines Work

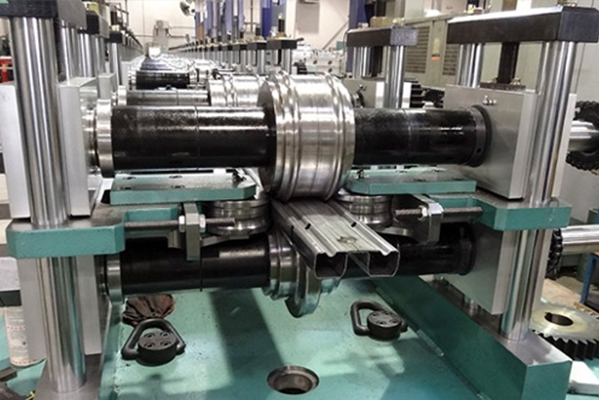

A steel silo roll forming machine is a specialized piece of equipment designed to shape metal coils into the curved panels needed to construct silos. Here’s how it works in simple terms:

Feeding the Metal Coil – The process starts with a large roll of steel sheet, which is fed into the machine.

Roll Forming – The machine passes the steel through a series of rollers that gradually bend it into the desired curved shape.

Cutting to Size – Once formed, the panels are cut to the required length, ready for assembly.

Assembly – These pre-formed panels are then transported to the construction site, where they are bolted or welded together to form the silo structure.

This method is much faster than traditional welding and cutting on-site, reducing labor costs and construction time.

Why They Matter in Large-Scale Storage

1. Speed and Efficiency

Building a silo from scratch using traditional methods can take weeks or even months. Roll forming machines streamline the process by producing uniform panels quickly, allowing for rapid assembly. This is especially important for industries that need to expand storage capacity in a short time, such as agriculture during harvest seasons.

2. Consistency and Precision

Manual fabrication can lead to variations in panel shapes, which may cause fitting issues during assembly. Roll forming machines ensure every panel is identical, resulting in a stronger, more reliable silo structure.

3. Cost-Effectiveness

By automating much of the fabrication process, these machines reduce labor costs and material waste. Since the panels are pre-formed, there’s less need for on-site adjustments, saving both time and money.

4. Durability

Steel silos made with roll-formed panels are known for their strength and resistance to weather, pests, and corrosion. This makes them ideal for long-term storage of sensitive materials like grain or industrial powders.

Where You’ll See Them in Action

Steel silos are used in various industries, including:

Agriculture – Storing grains, feed, and fertilizers.

Construction – Holding cement, fly ash, and other building materials.

Food Processing – Safeguarding ingredients like flour, sugar, and salt.

Without roll forming machines, producing these silos at scale would be far more challenging and expensive.

Final Thoughts

Steel silo roll forming machines may not be something we think about every day, but they play a crucial role in modern storage solutions. By enabling faster, more precise, and more economical silo production, they help industries maintain efficient and reliable storage systems. Whether it’s keeping our food supply secure or ensuring construction materials are stored safely, these machines are an essential part of large-scale storage infrastructure.

Next time you see a towering steel silo, you’ll know there’s a smart machine behind its smooth, sturdy walls!