Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Jun 24, 2025 Visit:79 Source:Roll Forming Machine Factory

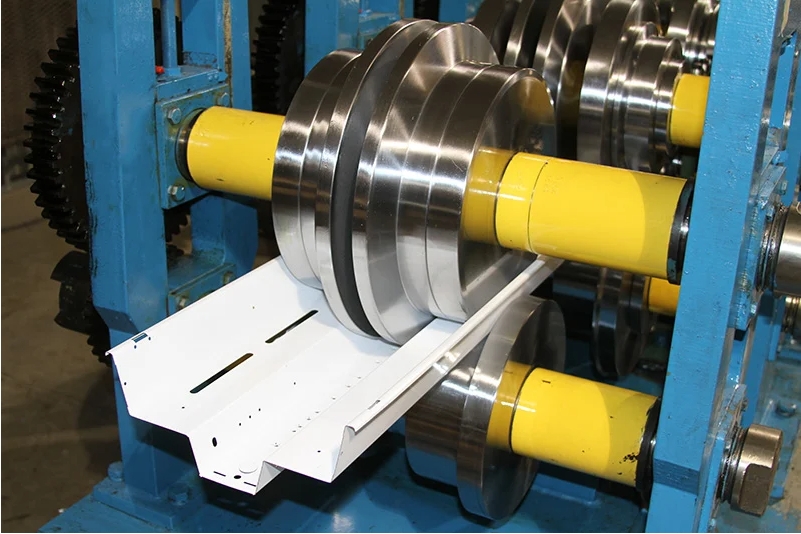

Custom rollforming has become an important process in modern construction, offering practical and cost-effective solutions for various building applications. This metal forming technique shapes continuous strips of metal into specific profiles, meeting the exact requirements of different construction designs. As building designs become more diverse, the demand for tailored metal components continues to grow. Here's how custom rollforming is contributing to today’s construction projects.

Precision and Consistency in Manufacturing

One of the key benefits of custom rollforming is its ability to produce metal parts with high consistency and accuracy. Whether it’s structural components, roofing systems, or wall panels, the process ensures that each piece meets the required specifications. This precision helps construction teams achieve proper fit and alignment, reducing the need for on-site adjustments.

Flexibility for Complex Designs

Modern construction projects often feature unique architectural elements and specialized structural needs. Custom rollforming provides the flexibility to create complex shapes, sizes, and profiles that standard off-the-shelf materials cannot easily offer. This adaptability supports architects and engineers in realizing creative designs without compromising on structural integrity.

Efficient Production for Large Volumes

Custom rollforming is well-suited for high-volume production, making it a reliable choice for large-scale construction projects. Once the tooling is set, the process can run continuously, producing long lengths of material quickly. This efficiency helps in meeting project deadlines and managing material costs effectively.

Wide Range of Applications

Custom rollformed products are widely used in commercial buildings, industrial facilities, warehouses, and infrastructure projects. Common applications include framing components, guardrails, purlins, gutters, and custom brackets. The versatility of the process allows manufacturers to serve different sectors with tailored solutions.

Material Optimization

Rollforming minimizes material waste by precisely cutting and shaping metal to the required lengths. This controlled process contributes to better resource management, which can lead to more streamlined procurement and reduced handling on-site.

Consistent Quality Control

Custom rollforming operations typically incorporate quality control measures throughout the production process. This ensures that each batch meets the project’s technical and performance standards. Consistent quality contributes to the durability and reliability of the final construction.

Conclusion

Custom rollforming plays a valuable role in modern construction by offering precision, flexibility, and efficiency. Its ability to produce tailored metal components that align with specific project needs supports the advancement of architectural and structural designs. As the construction industry continues to evolve, the advantages of custom rollforming make it a preferred solution for delivering reliable and cost-conscious building materials.