Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Mar 03, 2025 Visit:84 Source:Roll Forming Machine Factory

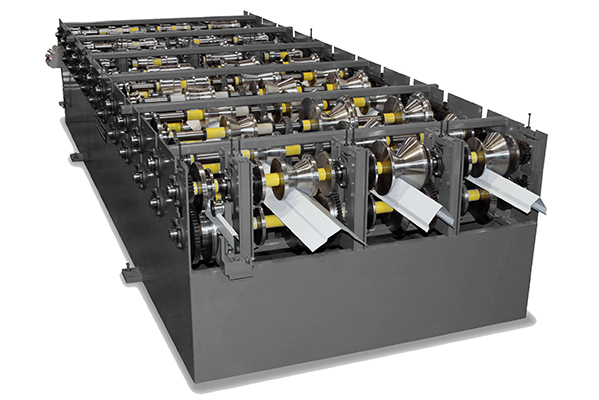

A rolling tool is an essential component in various industrial processes, designed to shape, flatten, or compress materials into desired forms. These tools are integral to the rolling process, which is widely used in metalworking, manufacturing, and other industries to produce sheets, plates, rods, and other profiles with precision and efficiency. The rolling tool plays a critical role in transforming raw materials into functional products, making it a cornerstone of modern production techniques.

What is a Rolling Tool?

A rolling tool typically consists of rollers, dies, or other mechanical components that apply pressure to a material as it passes through them. These tools are often part of rolling mills or specialized machinery, where they work in tandem to deform materials such as metal, plastic, or even food products. The design and configuration of a rolling tool depend on the specific application, whether it’s hot rolling, cold rolling, or roll forming.

Applications of Rolling Tools

The primary purpose of a rolling tool is to shape materials into usable forms. In the metal industry, rolling tools are used to produce flat sheets, coils, and structural components like beams and rails. In the automotive sector, they help create precision parts such as chassis components and body panels. Beyond metalworking, rolling tools are also used in the food industry to flatten dough, in the paper industry to compress materials, and in the plastics industry to create thin films or sheets.

Types of Rolling Tools

There are several types of rolling tools, each suited for specific tasks. Flat rolling tools are used to produce sheets and plates, while profile rolling tools create complex shapes like I-beams or T-sections. Thread rolling tools are specialized for forming threads on bolts and screws, and ring rolling tools are used to manufacture seamless rings for applications like bearings and turbines. Each type of tool is engineered to deliver precise results while minimizing material waste.

Advantages of Using Rolling Tools

The use of rolling tools offers numerous benefits. They enable high-speed production with consistent quality, making them ideal for large-scale manufacturing. Rolling tools also enhance the mechanical properties of materials, such as strength and durability, by aligning their grain structure during the deformation process. Additionally, the process is highly efficient, as it minimizes material waste and reduces the need for secondary machining.

Challenges and Innovations

Despite their advantages, rolling tools face challenges such as wear and tear, which can affect precision over time. High initial costs and the need for skilled operators can also be barriers. However, advancements in materials science, such as the use of hardened alloys and coatings, have extended the lifespan of rolling tools. Automation and computer-controlled systems have further improved accuracy and reduced labor requirements, making the process more accessible and cost-effective.

Conclusion

In conclusion, a rolling tool is a vital instrument in the rolling process, enabling the efficient and precise shaping of materials across a wide range of industries. From metalworking to food production, these tools play a pivotal role in transforming raw materials into functional products. As technology continues to advance, the capabilities of rolling tools will only expand, ensuring their continued importance in modern manufacturing and industrial processes.