Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Mar 12, 2025 Visit:87 Source:Roll Forming Machine Factory

The manufacturing of automotive parts is a highly specialized and intricate process that forms the foundation of the automotive industry. From engines and transmissions to body panels and electronic components, every part of a vehicle is meticulously designed and produced to meet strict quality and performance standards. The manufacturing of automotive parts involves a combination of advanced technologies, precision engineering, and rigorous testing to ensure reliability, durability, and safety. Let’s delve into the key stages of this fascinating process.

1. Design and Prototyping

The manufacturing of automotive parts begins with design and prototyping. Engineers and designers use computer-aided design (CAD) software to create detailed 3D models of each component. These designs are then tested virtually for performance, durability, and compatibility with other parts. Once the design is finalized, prototypes are produced using techniques like 3D printing or CNC machining. Prototyping allows manufacturers to identify and address potential issues before mass production begins.

2. Material Selection

Selecting the right materials is a critical step in the manufacturing of automotive parts. Materials must meet specific requirements for strength, weight, and durability. Common materials include high-strength steel, aluminum, plastics, and composites. For specialized components, such as engine parts or brake systems, materials like titanium or carbon fiber may be used. The choice of material directly impacts the performance and longevity of the part.

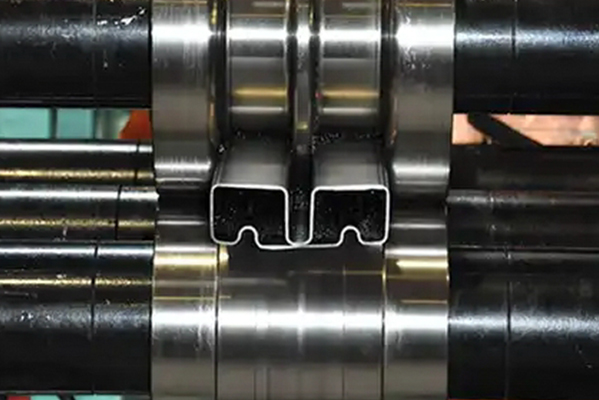

3. Stamping and Forming

For metal components, stamping and forming are essential processes in the manufacturing of automotive parts. Large stamping presses use dies to cut and shape metal sheets into the desired forms. This process is used to create body panels, frames, and structural components. Precision is crucial to ensure consistency and quality across thousands of parts. Advanced robotic systems are often employed to enhance accuracy and efficiency.

4. Casting and Machining

Casting is widely used in the manufacturing of automotive parts, particularly for engine blocks, cylinder heads, and transmission cases. Molten metal is poured into molds and allowed to cool, forming the basic shape of the part. After casting, machining processes such as milling, drilling, and grinding are used to achieve the final dimensions and surface finish. Computer numerical control (CNC) machines are commonly used for high-precision machining.

5. Welding and Assembly

Welding is a key process in the manufacturing of automotive parts, especially for assembling complex structures like chassis and exhaust systems. Robotic welding systems ensure consistent and high-quality welds, reducing the risk of defects. After welding, parts are assembled into larger components or subassemblies. This stage often involves both automated systems and skilled technicians to ensure proper fit and function.

6. Surface Treatment and Coating

Surface treatment is an important step in the manufacturing of automotive parts to enhance durability and performance. Processes like heat treatment, galvanizing, and anodizing are used to improve strength and resistance to wear and corrosion. Additionally, parts may be coated with paints, powders, or other protective layers to enhance appearance and longevity. For example, brake components are often coated to withstand high temperatures and friction.

7. Quality Control and Testing

Quality control is integral to the manufacturing of automotive parts. Each part undergoes rigorous inspection and testing to ensure it meets design specifications and industry standards. Techniques such as coordinate measuring machines (CMM), ultrasonic testing, and stress analysis are used to detect defects and verify dimensions. Functional tests, such as load testing for suspension components or pressure testing for fuel systems, are also conducted to ensure reliability.

8. Packaging and Distribution

Once parts pass quality control, they are carefully packaged to prevent damage during transportation. The manufacturing of automotive parts often involves just-in-time (JIT) delivery systems, where parts are shipped directly to assembly plants as needed. This approach minimizes inventory costs and ensures a steady supply of components for vehicle production.

Conclusion

The manufacturing of automotive parts is a complex and highly coordinated process that combines advanced technology, skilled craftsmanship, and rigorous quality control. From design and material selection to casting, machining, and assembly, each step is critical to producing parts that meet the high standards of the automotive industry. As the industry continues to evolve, innovations in materials, automation, and sustainability will further enhance the manufacturing of automotive parts, driving the future of mobility forward.