Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Jun 29, 2025 Visit:70 Source:Roll Forming Machine Factory

The heavy gauge rollforming industry is undergoing a significant transformation, driven by a wave of innovations that are enhancing efficiency, precision, and the capabilities of these robust machines. From advanced control systems to novel material handling techniques, these developments are setting new benchmarks for what's possible in manufacturing complex profiles from thick materials.

Advanced Automation and Robotics Integration

One of the most impactful trends is the deepening integration of advanced automation and robotics. While automation has long been a part of rollforming, the current focus is on more sophisticated, interconnected systems. This includes robotic arms for automated loading and unloading of heavy coils and finished parts, reducing manual labor and increasing throughput. Furthermore, intelligent automation allows for quicker changeovers between different product runs, minimizing downtime and boosting overall productivity. The aim is a "lights-out" operation where human intervention is significantly reduced, freeing up personnel for more analytical and supervisory roles.

Enhanced Control Systems and Software

The brain of the modern rollformer is its enhanced control system and software. We're seeing a shift towards highly intuitive interfaces that offer real-time data feedback and predictive analytics. These systems leverage advanced algorithms to optimize production parameters, such as speed, pressure, and tooling adjustments, based on material properties and desired part specifications. This level of control leads to superior product consistency and reduced material waste. Furthermore, the ability to simulate rollforming processes virtually before physical production is becoming more common, allowing for rapid prototyping and error correction.

Precision Tooling and Material Advances

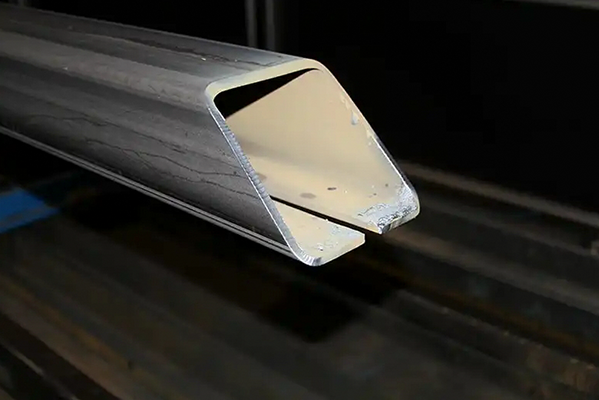

The evolution of precision tooling is critical for achieving tighter tolerances and more intricate profiles. New tool materials, coatings, and manufacturing techniques are extending tool life and improving surface finishes on formed parts. The development of segmented and interchangeable tooling systems also contributes to greater flexibility and reduced setup times. Concurrently, the industry is adapting to and benefiting from advances in the materials being processed. The ability to accurately form high-strength steels, specialized alloys, and other challenging materials is expanding the applications for heavy gauge rollforming across various sectors.

Integrated Quality Control and Monitoring

The future of heavy gauge rollforming is also defined by integrated quality control and monitoring systems. These systems often incorporate in-line sensors and vision systems that continuously inspect the formed profile for deviations from specifications. This real-time feedback loop allows for immediate adjustments to the forming process, preventing the production of out-of-spec parts and minimizing scrap. This proactive approach to quality ensures higher product reliability and reduces the need for extensive post-production inspections.

Connectivity and Data Exchange

The concept of the "connected factory" is increasingly relevant. Rollforming machines are being equipped with capabilities for seamless connectivity and data exchange. This allows for integration with broader manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms. The flow of data enables better production planning, inventory management, and overall operational visibility, paving the way for more responsive and adaptive manufacturing environments.

These innovations collectively paint a picture of a heavy gauge rollforming industry that is increasingly precise, efficient, and capable. As these advancements continue to mature, they will unlock new possibilities for manufacturing complex and high-performance components across a wide range of industries.