Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Mar 12, 2025 Visit:100 Source:Roll Forming Machine Factory

The automotive manufacturing process is a complex and highly coordinated series of steps that transform raw materials into the vehicles we drive every day. This workflow involves advanced technology, precision engineering, and meticulous planning to ensure efficiency, safety, and quality. From design to assembly, each stage of automotive manufacturing plays a critical role in delivering vehicles that meet consumer demands and regulatory standards.

1. Design and Development

The automotive manufacturing process begins with design and development. Engineers and designers collaborate to create vehicle concepts, focusing on aesthetics, functionality, and performance. Using computer-aided design (CAD) software, they develop detailed blueprints and 3D models. Prototypes are then built and tested to evaluate performance, safety, and durability. This phase ensures that the vehicle meets both customer expectations and industry regulations.

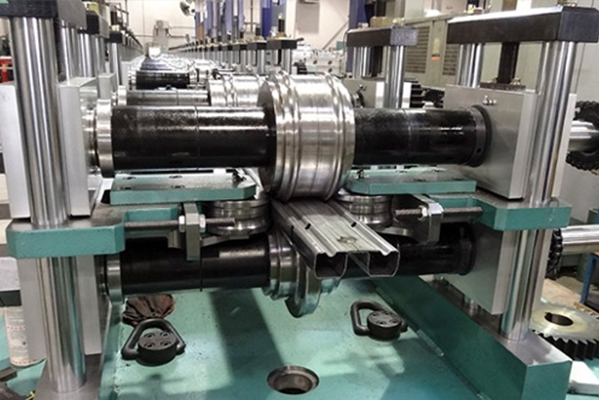

2. Sourcing and Stamping

Once the design is finalized, the next step in automotive manufacturing is sourcing materials. High-quality steel, aluminum, plastics, and other materials are procured from suppliers. These materials are then shaped into vehicle components through a process called stamping. Large stamping presses use dies to cut and form metal sheets into body panels, frames, and other structural parts. Precision is key at this stage to ensure consistency and quality.

3. Welding and Body Assembly

In the welding phase, stamped components are joined together to form the vehicle's body structure. Robotic welding systems are commonly used to ensure accuracy and efficiency. This stage creates the car's skeleton, known as the body-in-white. After welding, the body undergoes inspection to detect any defects or inconsistencies. This step is crucial in automotive manufacturing as it lays the foundation for the vehicle's structural integrity.

4. Painting

The painted finish not only enhances the vehicle's appearance but also protects it from corrosion and environmental damage. The painting process in automotive manufacturing involves several steps, including cleaning, priming, base coating, and clear coating. Advanced robotic systems apply paint evenly, ensuring a high-quality finish. The painted body is then cured in ovens to harden the paint and achieve durability.

5. Engine and Transmission Assembly

While the body is being prepared, the engine and transmission are assembled separately. These components are the heart of the vehicle, and their assembly requires precision engineering. Skilled technicians and automated systems work together to build and test these critical parts. Once completed, they are ready to be integrated into the vehicle during final assembly.

6. Final Assembly

The final assembly stage is where all the components come together. The painted body is mounted on an assembly line, and the engine, transmission, suspension, interior components, and electrical systems are installed. This phase of automotive manufacturing involves both manual labor and automated systems, ensuring that every part is correctly fitted and functional. Quality checks are performed throughout the process to maintain high standards.

7. Testing and Quality Control

Before a vehicle leaves the factory, it undergoes rigorous testing and quality control. This includes functional tests, safety inspections, and performance evaluations. Any issues identified are addressed immediately to ensure the vehicle meets all specifications. This final step in automotive manufacturing guarantees that the vehicle is safe, reliable, and ready for the road.

Conclusion

The automotive manufacturing process workflow is a testament to human ingenuity and technological advancement. From design to final assembly, each step is carefully orchestrated to produce vehicles that are efficient, safe, and aesthetically pleasing. As the industry continues to evolve, innovations in automation, sustainability, and materials will further enhance the automotive manufacturing process, shaping the future of transportation.