Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Jul 12, 2025 Visit:70 Source:Roll Forming Machine Factory

The selection of materials for lighting channel production is a critical decision that directly impacts the product's performance, durability, and cost-effectiveness. Several key factors guide manufacturers in this process, each playing a significant role in the final design and functionality of the lighting solution.

Mechanical Properties

The mechanical properties of a material are paramount. Lighting channels, especially those used in commercial or industrial settings, must withstand various stresses, including the weight of the lights themselves, potential impacts, and vibrational forces. Materials need to exhibit sufficient strength and rigidity to maintain their form and support the lighting fixtures without warping or deforming over time. Impact resistance is also crucial, particularly in areas where accidental bumps or drops could occur. For instance, a material with high tensile strength would be suitable for long, suspended channels, while one with excellent compressive strength would be preferred for recessed applications.

Thermal Management

Effective thermal management is another fundamental consideration. Lighting, particularly LED technology, generates heat. The material chosen for the channel must be able to dissipate this heat efficiently to prevent overheating of the lighting components, which can significantly reduce their lifespan and performance. Materials with high thermal conductivity, such as certain aluminum alloys, are often favored for this reason. Conversely, materials with poor thermal conductivity might necessitate additional heat sinks or a more complex design to manage heat buildup.

Optical Properties

The optical properties of the material are critical, especially when the channel itself interacts with the light output. For diffusers or lenses integrated into the channel, light transmission and diffusion characteristics are key. Materials should allow for the desired amount of light to pass through while effectively diffusing it to minimize glare and create a uniform illumination. Factors like clarity, haze, and color rendering index (CRI) impact need to be carefully evaluated to ensure the lighting quality meets specifications.

Manufacturing Process and Cost

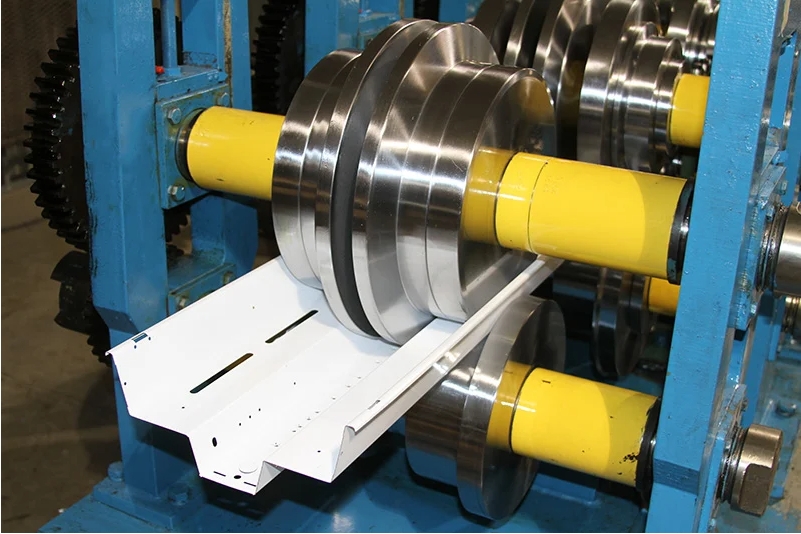

The manufacturing process inherently influences material selection. The ease with which a material can be fabricated, molded, extruded, or machined directly impacts production efficiency and cost. Some materials are highly adaptable to various manufacturing techniques, offering flexibility in design. Coupled with this is cost. While performance is vital, the overall material cost and the cost of processing it must align with the product's target market and pricing strategy. Manufacturers often seek a balance between optimal material properties and economic viability.

Durability and Environmental Factors

The intended environment for the lighting channel heavily influences durability requirements. Materials must be resistant to corrosion, UV degradation, and chemical exposure if the channel is to be used outdoors or in specific industrial environments. For example, channels exposed to direct sunlight require materials that can withstand prolonged UV radiation without becoming brittle or discolored. The expected lifespan of the product also dictates the level of material durability required.

In conclusion, the decision-making process for selecting materials in lighting channel production is a multifaceted one. It requires a thorough understanding of mechanical, thermal, and optical requirements, alongside considerations of manufacturability, cost, and the specific operational environment. By carefully balancing these factors, manufacturers can produce lighting channels that are not only functional and efficient but also robust and cost-effective.