Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Jul 03, 2025 Visit:71 Source:Roll Forming Machine Factory

Choosing the right grain storage manufacturing equipment is essential for maintaining grain quality, optimizing operational efficiency, and ensuring long-term storage viability. Several factors must be carefully evaluated to make an informed decision. Below are the primary considerations when selecting grain storage equipment.

1. Storage Capacity and Scalability

The equipment should align with current storage needs while allowing for future expansion. Assess the volume of grain to be stored and whether the system can be scaled up as demand increases. Modular designs or adjustable configurations can provide flexibility for varying storage requirements.

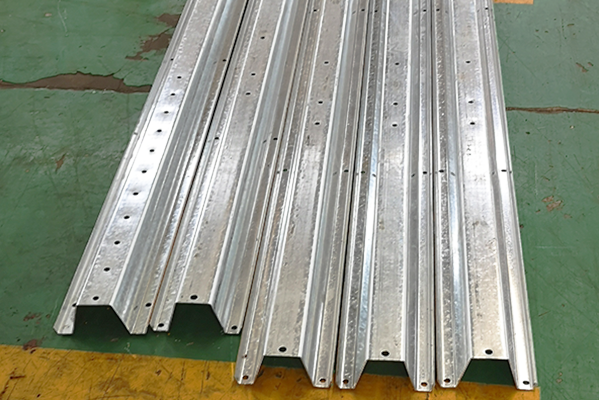

2. Durability and Material Quality

High-quality materials such as galvanized steel or reinforced polymers enhance durability and resistance to environmental factors. The equipment should withstand moisture, temperature fluctuations, and potential pest exposure without compromising structural integrity.

3. Grain Preservation Features

Effective grain storage requires features that minimize spoilage and maintain quality. Look for equipment with proper aeration systems, moisture control mechanisms, and sealing capabilities to prevent mold, insects, and rodent infestations.

4. Ease of Installation and Maintenance

Equipment that is easy to install and maintain reduces downtime and operational costs. Consider systems with accessible components, straightforward assembly processes, and minimal maintenance requirements to ensure smooth long-term operation.

5. Automation and Monitoring Capabilities

Modern grain storage solutions often include automation for temperature and humidity control, as well as real-time monitoring systems. These features help in maintaining optimal storage conditions and reducing manual intervention.

6. Cost-Effectiveness and Return on Investment

While initial costs are important, long-term value should also be evaluated. Compare different equipment options based on lifespan, efficiency, and potential savings in labor and grain loss reduction.

7. Compliance with Industry Standards

Ensure the equipment meets relevant industry regulations and safety standards. Compliance helps avoid legal issues and ensures the system operates safely and effectively.

8. Supplier Reputation and Support

Choose a reputable manufacturer with a track record of reliable products and strong customer support. Warranty coverage, availability of spare parts, and technical assistance are crucial for uninterrupted operations.

Conclusion

Selecting the right grain storage manufacturing equipment involves balancing capacity, durability, preservation features, and cost considerations. By evaluating these factors, businesses can invest in a system that ensures grain quality, operational efficiency, and long-term reliability. Proper research and supplier assessment will help in making a well-informed decision.