Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Mar 14, 2025 Visit:79 Source:Roll Forming Machine Factory

For farmers, effective grain storage is a critical step in ensuring the quality and longevity of their harvest. Proper storage protects grains from moisture, pests, and spoilage, allowing farmers to maximize their yields and profits. To achieve this, farmers rely on a variety of tools and structures, many of which are produced by advanced grain storage manufacturing equipment. This article explores the primary methods and equipment farmers use to store grain and how modern technology has revolutionized grain storage practices.

Traditional vs. Modern Grain Storage Solutions

Historically, farmers stored grain in simple structures like pits, clay pots, or wooden bins. While these methods were effective for small-scale storage, they often fell short in protecting grains from pests, moisture, and environmental factors. Today, thanks to innovations in grain storage manufacturing equipment, farmers have access to more reliable and efficient solutions that can handle larger volumes and provide better protection.

Key Tools and Structures for Grain Storage

1.Silos:

Silos are the most iconic structures used for grain storage. Made from steel or concrete, modern silos are designed to be airtight and durable, protecting grains from moisture, pests, and temperature fluctuations. Grain storage manufacturing equipment has enabled the production of silos with advanced features like temperature control systems and automated unloading mechanisms.

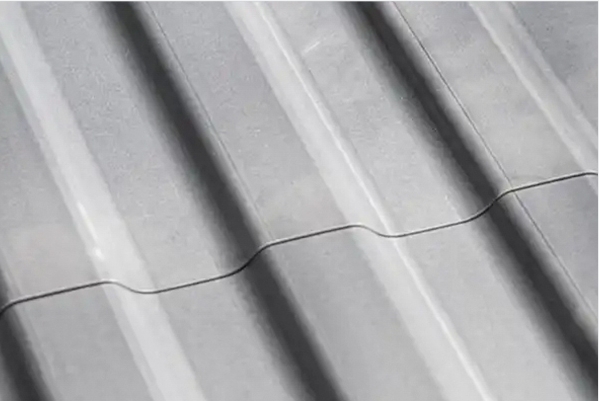

2.Grain Bins:

Grain bins, often made of corrugated steel, are another popular choice for farmers. These bins are versatile, cost-effective, and can be equipped with aeration systems to maintain grain quality. Modern grain storage manufacturing equipment ensures these bins are built to withstand harsh weather conditions and provide long-term storage solutions.

3.Hermetic Bags:

Hermetic storage bags, made from multi-layer polyethylene, create an oxygen-free environment that prevents pest infestations and spoilage. These bags are portable, affordable, and ideal for small to medium-scale farmers. They are a product of innovative grain storage manufacturing equipment designed for convenience and efficiency.

4.Aeration Systems:

Aeration is crucial for maintaining grain quality during storage. Farmers use aeration systems, integrated into silos or bins, to circulate air and regulate temperature and moisture levels. These systems, produced by specialized grain storage manufacturing equipment, help prevent mold and fungal growth.

5.Temperature and Humidity Monitors:

Precision monitoring tools are essential for modern grain storage. These devices, often connected to automated systems, track environmental conditions inside storage structures and alert farmers to any changes that could compromise grain quality.

The Role of Grain Storage Manufacturing Equipment

The advancements in grain storage manufacturing equipment have transformed how farmers store their grain. Manufacturers now produce equipment that is not only durable but also equipped with smart technologies. For example, automated silos with IoT-enabled monitoring systems allow farmers to track storage conditions remotely, ensuring optimal preservation with minimal effort.

Conclusion

Farmers today have access to a wide range of tools and structures for grain storage, thanks to innovations in grain storage manufacturing equipment. From silos and grain bins to hermetic bags and aeration systems, these solutions ensure that grains are stored safely and efficiently.