Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Jul 03, 2025 Visit:70 Source:Roll Forming Machine Factory

The grain storage manufacturing industry is evolving to meet the demands of modern agriculture, with several important trends driving innovation. These developments focus on improving efficiency, durability, and operational effectiveness while addressing the challenges of global food supply chains.

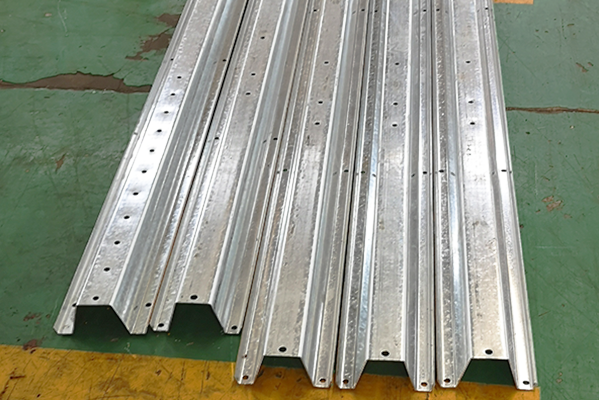

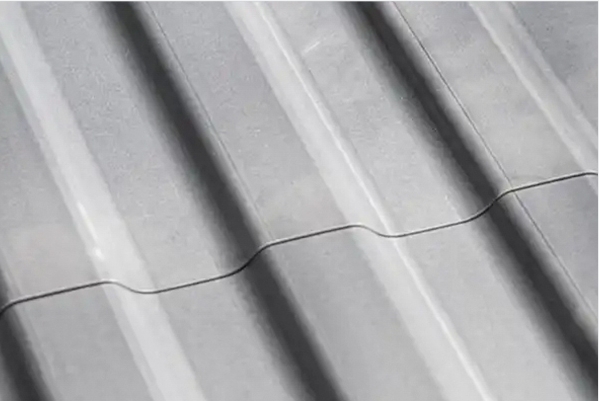

1. Advanced Material Technologies

Manufacturers are increasingly using high-strength, corrosion-resistant materials to extend the lifespan of grain storage systems. Innovations in steel coatings and composite materials help protect stored grain from moisture and pests, reducing spoilage and maintaining quality.

2. Automation and Smart Monitoring Systems

The integration of automation and IoT-enabled sensors allows for real-time monitoring of grain conditions, including temperature, humidity, and CO₂ levels. These systems enable farmers and storage operators to make data-driven decisions, preventing losses and optimizing storage conditions.

3. Modular and Scalable Storage Solutions

Demand for flexible storage options is growing, particularly in regions with fluctuating harvest yields. Modular grain storage systems allow for easy expansion or reconfiguration, providing cost-effective solutions for farms and commercial storage facilities.

4. Improved Aeration and Climate Control

Enhanced aeration systems ensure proper airflow within storage units, preventing mold and maintaining grain quality. Some manufacturers are incorporating adaptive climate control technologies that adjust ventilation based on external weather conditions.

5. Efficient Loading and Unloading Mechanisms

New designs in grain storage structures focus on streamlining the loading and unloading process. Features such as integrated conveyor systems and optimized hopper designs reduce labor requirements and minimize grain handling losses.

6. Global Standardization and Compliance

As international grain trade expands, manufacturers are designing storage solutions that meet global safety and quality standards. Compliance with regulations ensures smoother cross-border transactions and reduces risks related to contamination or spoilage.

7. Cost-Effective and Long-Lasting Designs

Economic pressures are driving the development of more affordable yet durable storage options. Manufacturers are balancing upfront costs with long-term value, ensuring that storage systems remain viable investments for years.

Conclusion

The future of grain storage manufacturing is being shaped by advancements in materials, automation, and design efficiency. These trends contribute to more reliable and adaptable storage solutions, supporting the agricultural sector in meeting the demands of a growing population. By adopting these innovations, industry stakeholders can enhance grain preservation and optimize supply chain operations.