Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Jun 29, 2025 Visit:69 Source:Roll Forming Machine Factory

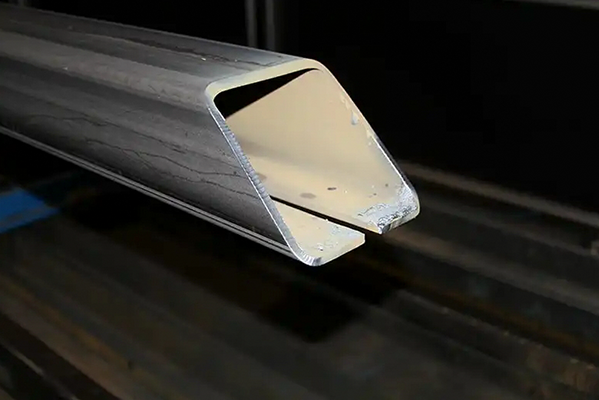

Heavy gauge rollforming systems play a vital role in fabricating structural and industrial-grade components from thick metal sheets. While these systems offer considerable production advantages, they also bring operational challenges that must be addressed to ensure consistent performance, safety, and product quality. Below are some of the primary difficulties encountered when running heavy gauge rollforming equipment.

1. Material Handling and Feeding

Heavy gauge materials are significantly thicker and heavier than standard coil stock, requiring specialized handling equipment and robust feeding mechanisms. Improper material alignment or tension control can lead to feeding inaccuracies, increased wear on the rollers, or even material jams that cause downtime. Operators must ensure that decoilers, straighteners, and feeders are properly calibrated for each material type.

2. Machine Stress and Component Wear

The added force required to form thick metal sheets places substantial stress on the machine’s structure, drives, and tooling. Over time, this can accelerate wear on key components such as bearings, shafts, and roll tooling. Preventive maintenance and the use of durable tool steels or coatings are essential to extend equipment life and maintain consistent output.

3. Tooling Design Complexity

Designing roll tooling for heavy gauge materials is more complex due to the material’s resistance to deformation. Each pass must be carefully engineered to gradually form the profile without introducing stress fractures or deformation. Additionally, adjustments may be needed depending on material thickness, tensile strength, and surface finish, which can complicate the setup process.

4. Power and Drive Requirements

Heavy gauge rollforming requires significantly more torque and horsepower than light gauge applications. Motors, gearboxes, and drives must be sized appropriately to handle increased loads. Undersized components can lead to overheating, mechanical failure, or inconsistent forming speeds. Upgrading to variable frequency drives (VFDs) can help manage these loads more efficiently.

5. Forming Accuracy and Tolerances

Maintaining tight tolerances in heavy gauge profiles is more challenging due to springback and material memory. Even small misalignments in tooling or variations in material thickness can cause profile distortion. Continuous monitoring and real-time adjustments, often aided by sensors or digital controls, are necessary to ensure dimensional accuracy.

6. Safety and Operator Training

Operating heavy gauge systems involves greater risks due to the sheer weight and force involved in the process. Proper training is critical to ensure operators understand safe loading practices, emergency shutdown procedures, and correct handling of formed parts. Additionally, machines should be equipped with safety features such as guarding, interlocks, and overload protection.

7. Production Flexibility

Heavy gauge systems are often designed for high-volume runs of specific profiles, making changeovers more time-consuming. Modifying tooling for different profile types or material grades can be a lengthy and labor-intensive process. Businesses that require a high degree of product variation must consider modular tooling systems or quick-change features to enhance flexibility.

Conclusion

Operating heavy gauge rollforming systems presents a unique set of challenges that span mechanical design, process control, safety, and maintenance. Manufacturers who invest in robust machinery, proactive maintenance programs, and skilled personnel can overcome these obstacles and realize the full potential of their rollforming operations. By understanding and addressing these key challenges, companies can improve efficiency, reduce downtime, and consistently produce high-quality components that meet industry standards.