Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Mar 31, 2025 Visit:81 Source:Roll Forming Machine Factory

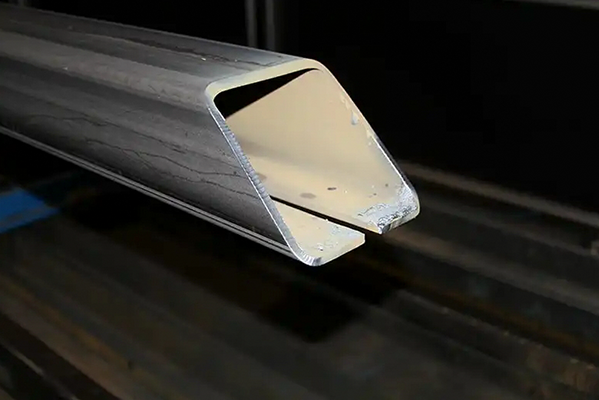

Thick gauge roll forming lines are specialized manufacturing systems designed to shape heavy-duty metal sheets or coils (typically 3 mm to over 20 mm in thickness) into high-strength, continuous profiles with precise cross-sectional geometries. These lines are integral to industries requiring robust, durable components, leveraging the efficiency and precision of roll forming technology. Below, we explore the diverse applications of thick gauge roll forming lines and their critical role in modern industrial processes.

1. Construction and Structural Engineering

Thick gauge roll forming lines are widely used to produce structural components for large-scale construction projects. Examples include:

Steel Beams and Columns: Heavy-gauge profiles serve as primary load-bearing elements in skyscrapers, bridges, and industrial facilities. Their high strength-to-weight ratio ensures structural stability while reducing material costs.

Seismic-Resistant Frameworks: Roll-formed thick-walled steel tubes and channels are essential in earthquake-prone regions due to their durability and ability to absorb dynamic loads.

Roof and Wall Systems: Custom profiles for roofing trusses and wall panels combine weather resistance with rapid assembly, streamlining construction timelines.

2. Oil and Gas Infrastructure

The energy sector relies on thick gauge roll forming for pipelines and drilling equipment:

High-Pressure Pipelines: Thick-walled steel tubes produced via roll forming withstand extreme pressures and corrosive environments, ensuring safe transport of oil and gas.

Drilling Rig Components: Heavy-duty brackets and supports for offshore platforms require precision-formed profiles to endure harsh marine conditions.

3. Transportation and Automotive Manufacturing

Roll forming enables the production of lightweight yet strong components for vehicles:

Commercial Vehicle Chassis: Thick-gauge steel profiles form the backbone of truck frames, trailers, and railcar structures, offering exceptional load-bearing capacity.

Automotive Structural Parts: Advanced high-strength steel (AHSS) profiles, such as crash-resistant beams, enhance vehicle safety while reducing weight.

4. Renewable Energy Systems

The renewable energy sector leverages thick gauge roll forming for critical infrastructure:

Wind Turbine Towers: Roll-formed steel sections provide the rigidity needed for tall turbine towers, which must withstand wind loads and torsional stresses.

Solar Panel Mounting Systems: Custom brackets and rails ensure precise alignment and longevity in solar farms.

5. Heavy Machinery and Industrial Equipment

Thick gauge profiles are indispensable in manufacturing machinery:

Mining Equipment: Components like conveyor frames and hydraulic cylinder housings require wear-resistant, high-tensile steel formed to exact specifications.

Agricultural Machinery: Durable plowshares and harvester parts benefit from the corrosion resistance of roll-formed stainless steel or coated alloys.

6. Aerospace and Defense Applications

While less common, thick gauge roll forming is used for specialized aerospace components:

Aircraft Landing Gear Parts: High-strength aluminum or titanium profiles ensure reliability under extreme stress.

Military Vehicle Armor: Roll-formed ballistic-grade steel plates provide lightweight protection for armored vehicles.

Advantages of Thick Gauge Roll Forming

Material Efficiency: Continuous processing minimizes scrap, especially for high-cost alloys.

Precision and Consistency: Computer-controlled systems achieve tolerances as tight as ±0.5 mm, critical for load-bearing applications.

Versatility: Adjustable roller dies allow rapid switching between profiles, supporting small-batch customization.

Strength Retention: Cold-forming preserves metallurgical properties, avoiding heat-induced weaknesses.

Challenges and Innovations

While thick gauge roll forming excels in many areas, challenges include high tooling costs and limitations in handling ultra-thick (>25 mm) materials. Innovations such as hybrid systems (combining roll forming with laser cutting) and IoT-enabled predictive maintenance are addressing these issues, enhancing productivity and expanding application scopes.

Conclusion

Thick gauge roll forming lines are a cornerstone of industrial manufacturing, enabling the cost-effective production of high-strength components for construction, energy, transportation, and beyond. As industries increasingly prioritize lightweight, sustainable designs, advancements in automation and material science will further solidify the role of roll forming in meeting global infrastructure demands. By integrating smart technologies and expanding material capabilities, these systems are poised to drive innovation across sectors, ensuring resilience and efficiency in an evolving industrial landscape.