Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Jul 12, 2025 Visit:66 Source:Roll Forming Machine Factory

In today's dynamic manufacturing landscape, the ability to pivot quickly and efficiently to meet evolving demands is no longer a luxury, but a necessity. For lighting manufacturers, this often translates to navigating high-precision demand shifts – sudden changes requiring tighter tolerances, specialized components, or unique product configurations. The question then becomes: is your production line truly prepared?

The shift from mass-produced, standardized lighting units to more bespoke, high-precision products requires a fundamental re-evaluation of current operational models. A production line optimized solely for volume may struggle when faced with the intricacies of bespoke orders or rapidly changing specifications.

Key Indicators of Readiness

Several factors determine a lighting production line's ability to handle high-precision demand shifts. Consider the following:

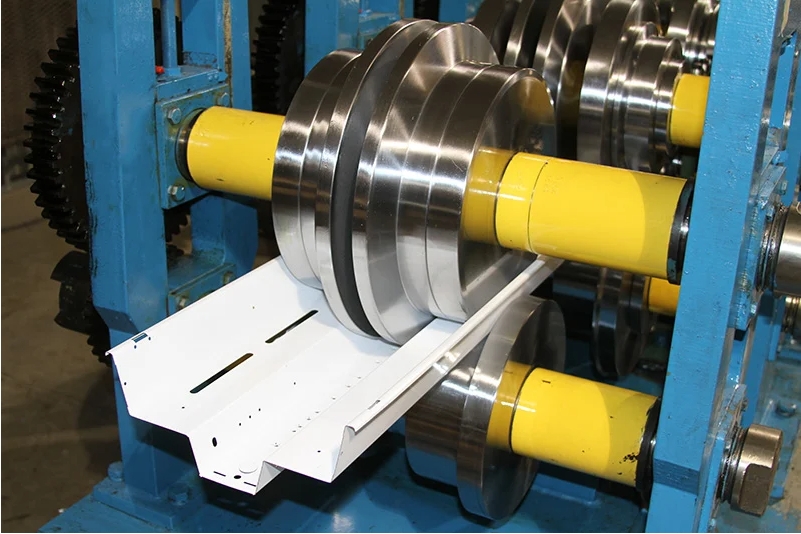

Adaptable Equipment: Can your current machinery be quickly re-calibrated or re-tooled for different product dimensions, component placements, or assembly sequences? Manual adjustments and lengthy downtime for changeovers significantly hinder responsiveness. Look for systems with modular designs and automated setup capabilities.

Precision Control Systems: The accuracy of your output directly correlates with the sophistication of your control systems. Are you relying on outdated or less precise methods for quality checks and component placement? Modern vision systems, robotic automation, and advanced metrology tools are crucial for achieving and maintaining tight tolerances.

Skilled Workforce: High-precision manufacturing demands a highly trained and adaptable workforce. Are your technicians and operators proficient in handling complex machinery, interpreting intricate specifications, and performing precise adjustments? Continuous training and upskilling programs are vital.

Efficient Material Flow and Inventory Management: Shifting demands often mean managing a wider variety of components, potentially in smaller batches. An optimized material handling system and a flexible inventory strategy are essential to prevent bottlenecks and ensure timely access to specialized parts.

Data-Driven Insights: Can you quickly analyze production data to identify bottlenecks, track precision metrics, and predict potential issues? Real-time data collection and analysis enable proactive adjustments, preventing costly errors and delays when precision is paramount.

The Cost of Unreadiness

Failing to adapt to high-precision demand shifts can lead to significant repercussions. These include increased scrap rates, extended lead times, customer dissatisfaction, and ultimately, a loss of competitive advantage. In a market increasingly valuing customization and specialized solutions, the inability to deliver on precision demands can be a critical limitation.

Preparing for Tomorrow's Demands Today

Proactively assessing and upgrading your lighting production line is an investment in future resilience. By focusing on equipment flexibility, advanced control, workforce development, streamlined material flow, and data utilization, you can ensure your operations are not just capable, but truly poised to meet the evolving and often high-precision demands of the market.