Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:May 19, 2025 Visit:59 Source:Roll Forming Machine Factory

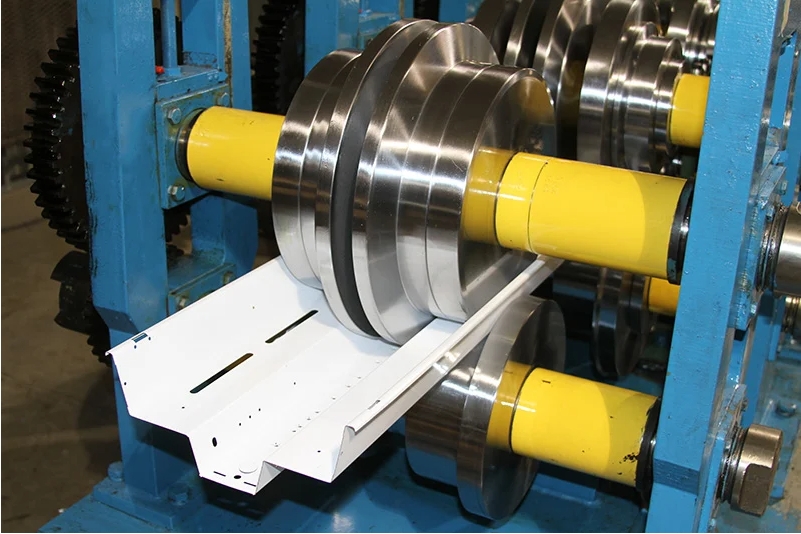

The lighting industry continues to evolve with advancements in manufacturing technology, and one of the key innovations driving this change is the roll forming machine. These machines play a crucial role in producing high-quality, consistent, and cost-effective lighting components. By integrating roll forming machines into production processes, manufacturers in the lighting industry can enhance efficiency, improve product durability, and meet growing market demands.

The Role of Roll Forming Machines in Lighting Manufacturing

Roll forming machines are designed to shape metal sheets into precise profiles through a series of rollers. In the lighting industry, these machines are used to create:

Lighting housings and fixtures – Ensuring uniformity in design and structural integrity.

LED channel systems – Providing durable and lightweight frames for LED installations.

Reflectors and heat sinks – Improving light distribution and thermal management.

By utilizing roll forming machines, manufacturers can produce complex shapes with tight tolerances, reducing material waste and increasing production speed.

Advantages of Using Roll Forming Machines in the Lighting Industry

Consistency and Precision – Roll forming ensures that each component meets exact specifications, which is essential for high-performance lighting products.

Cost Efficiency – The automated process reduces labor costs and minimizes material waste, making production more economical.

Scalability – Whether for small custom orders or large-scale production, roll forming machines can adapt to varying demands in the lighting industry.

Enhanced Durability – The formed metal components provide long-lasting performance, crucial for both indoor and outdoor lighting applications.

Future Trends: Automation and Customization

As the lighting industry embraces smart lighting and energy-efficient designs, roll forming machines are becoming more advanced. Automation allows for faster production cycles, while CNC-controlled systems enable greater customization. This flexibility ensures that manufacturers can keep up with evolving design trends and consumer preferences.

Conclusion

The integration of roll forming machines in the lighting industry has significantly improved manufacturing efficiency and product quality. As technology continues to advance, these machines will play an even greater role in producing innovative lighting solutions. For manufacturers looking to stay competitive, investing in modern roll forming machines is a strategic move toward sustainable growth.

By optimizing production processes with roll forming machines, the lighting industry can continue to deliver high-performance, reliable, and aesthetically appealing lighting solutions for various applications.