Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Aug 01, 2025 Visit:81 Source:Roll Forming Machine Factory

In recent years, global agricultural output has steadily increased, driven by population growth and changing food consumption patterns. This shift has led to rising demand for reliable grain storage solutions. As a result, manufacturers of grain storage equipment are actively evolving their technologies and production methods to better meet global needs.

Focus on Efficiency and Precision

Modern grain storage manufacturing equipment is being designed with a strong focus on efficiency. Automated forming lines, CNC-controlled cutting systems, and high-speed roll forming machines have become more common in production facilities. These upgrades help manufacturers deliver consistent quality at scale while reducing manual intervention. Improved precision also enhances the structural integrity of storage systems such as steel silos, ensuring durability and better protection of stored grain.

Modular and Scalable Solutions

The global market requires adaptable storage options for varying climate conditions, crop types, and facility sizes. In response, equipment manufacturers are developing modular systems that can be customized or expanded as needed. These modular systems support a range of storage capacities and allow for easy transportation and on-site installation, making them suitable for both large-scale agricultural operations and smaller regional facilities.

Integration with Digital Systems

To improve operational oversight, grain storage manufacturing equipment is increasingly being integrated with digital systems. Smart sensors, remote monitoring tools, and automated controls are becoming essential components in modern grain storage facilities. While not all of these technologies are embedded during the manufacturing stage, equipment producers are now building compatibility into their machines, ensuring smoother integration with digital infrastructure post-installation.

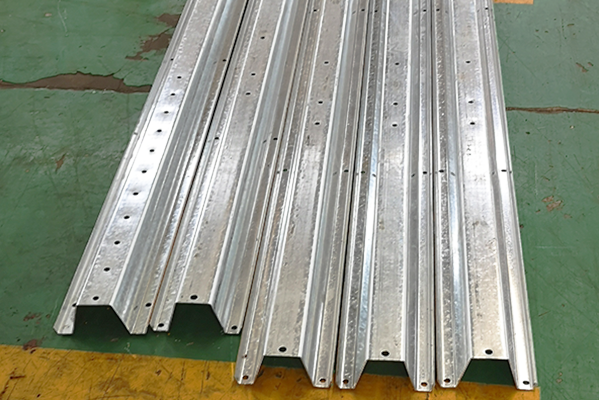

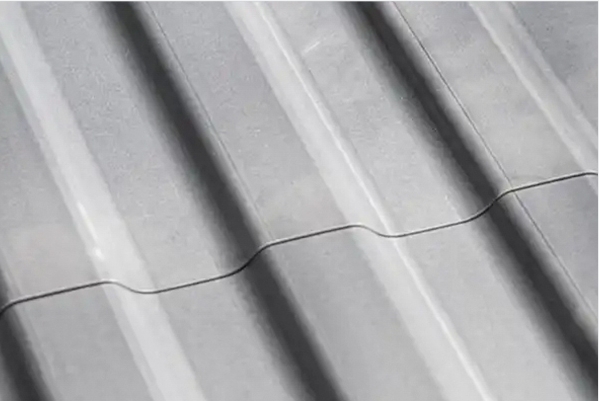

Material and Design Innovations

Material improvements are playing a significant role in the evolution of grain storage manufacturing equipment. High-tensile galvanized steel, corrosion-resistant coatings, and sealed joints are being prioritized to extend the life of storage units. At the same time, design optimizations such as improved ventilation structures and smoother inner walls contribute to better grain aeration and reduced spoilage.

Responding to Regional Needs

Manufacturers are also tailoring equipment solutions to meet regional and climatic requirements. In areas prone to high humidity or temperature variations, equipment designs are adjusted to maintain storage quality. This localization approach has helped manufacturers serve diverse markets across continents, from North America to Southeast Asia.

Expanding Global Production Capacity

To cope with growing international demand, several manufacturers are investing in global expansion, establishing new production lines or partnerships abroad. These moves not only reduce delivery lead times but also allow for closer collaboration with regional agricultural enterprises and contractors.

Conclusion

As the global need for grain storage increases, equipment manufacturers are adapting through smarter production processes, scalable designs, and improved material use. The industry’s ability to respond to these evolving demands plays a critical role in supporting agricultural stability worldwide. For businesses and investors in the grain supply chain, keeping up with these trends is essential for long-term competitiveness.