Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Apr 24, 2025 Visit:85 Source:Roll Forming Machine Factory

The forming process is a way to shape materials into different parts or products. It’s used in many industries, like car manufacturing, construction, and electronics. The basic idea is simple: you take a raw material (like metal, plastic, or glass) and change its shape without cutting or removing much of it.

Common Forming Methods

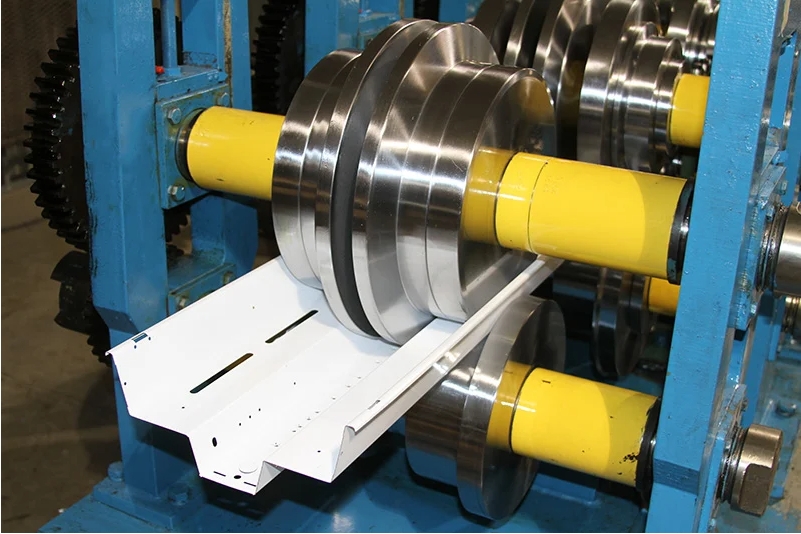

Rolling – A metal sheet or bar is passed through rollers to make it thinner or give it a certain shape. This is how things like aluminum foil and steel beams are made.

Forging – A piece of metal is heated and then hammered or pressed into shape. This makes strong parts like engine components or tools.

Stamping – A machine presses a sheet of metal (or other material) into a die to create a specific shape. Car body panels and metal containers are often made this way.

Extrusion – Material (like plastic or metal) is pushed through a shaped opening to create long pieces with the same cross-section. Pipes and window frames are common examples.

Drawing – A metal wire or tube is pulled through a die to make it longer and thinner. This is how electrical wires and certain tubes are produced.

Why Use Forming?

Forming is efficient because it doesn’t waste much material. It can also make parts stronger by aligning the material’s structure in a certain way. Plus, once the tools (like dies or molds) are set up, the process can be repeated quickly for mass production.

Limitations

Some forming methods need high heat or force, which can be expensive. Also, complex shapes might require multiple steps or additional machining.

In short, forming is a key manufacturing process that helps turn raw materials into useful parts with minimal waste. Different methods are chosen based on the material, desired shape, and production needs.