Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Jun 22, 2025 Visit:58 Source:Roll Forming Machine Factory

In recent years, the automotive industry has undergone significant changes driven by evolving design requirements, precision demands, and the need for higher production efficiency. Among the technologies supporting this transformation, roll forming machines are playing an increasingly vital role in reshaping automotive component manufacturing.

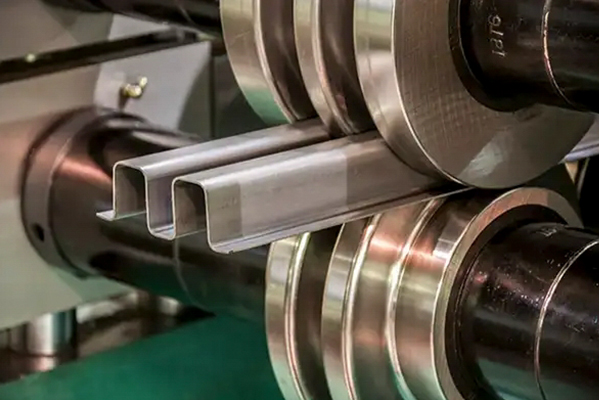

Enhanced Precision for Complex Designs

Roll formers provide the ability to manufacture automotive components with consistent cross-sectional profiles and tight dimensional tolerances. Automotive designs today often involve intricate structures that require reliable forming methods. Roll forming machines can handle these complex shapes with repeatable accuracy, which is essential for maintaining quality across large production volumes.

Support for Lightweight Structures

Automotive manufacturers are consistently working to balance vehicle strength with overall weight reduction. Roll forming technology efficiently processes high-strength materials like advanced steels and certain alloys. By using roll formers, manufacturers can create lighter yet strong components such as side impact beams, door reinforcements, and roof rails, which contribute to overall vehicle performance.

High Production Speed

One of the key benefits of roll forming in automotive manufacturing is its ability to support continuous, high-speed production. Unlike other forming processes that may require frequent interruptions for adjustments, roll forming allows for uninterrupted material feeding and shaping. This capability helps automotive companies meet tight production deadlines and manage large-scale manufacturing efficiently.

Material Versatility

Roll formers can process a wide range of materials, including various grades of steel, aluminum, and coated metals. This flexibility enables automotive suppliers to produce components for different vehicle categories and design requirements without significant changes to their production setups. It also allows for quicker adaptation to new project specifications.

Cost-Effective Manufacturing

Roll forming is well-suited for long production runs, making it a cost-effective choice for manufacturing large quantities of automotive components. The process minimizes material waste, reduces the need for secondary operations, and offers relatively low tooling costs compared to other shaping methods. This makes roll forming an attractive solution for automotive companies aiming to optimize production expenses.

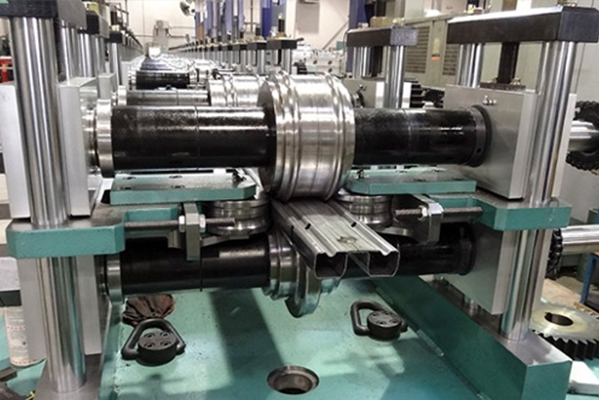

Integration with Modern Automation

Many roll forming lines used in automotive facilities today are integrated with automated systems such as inline cutting, punching, and quality inspection. This integration enhances production efficiency and consistency, while also supporting traceability and real-time monitoring of the manufacturing process.

Conclusion

Roll forming technology is steadily transforming the way automotive components are manufactured. By offering precise forming capabilities, high-speed production, material versatility, and cost efficiency, roll formers have become essential equipment in modern automotive manufacturing. As automotive designs continue to evolve, the role of roll forming machines is expected to grow, supporting manufacturers in meeting complex design standards and production demands.