Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Aug 03, 2025 Visit:65 Source:Roll Forming Machine Factory

Durability is a critical factor in grain storage, as equipment must withstand harsh environmental conditions, heavy loads, and long-term use. Manufacturers are implementing advanced materials, engineering techniques, and protective measures to ensure grain storage solutions remain robust and reliable. Here’s how they are achieving greater durability.

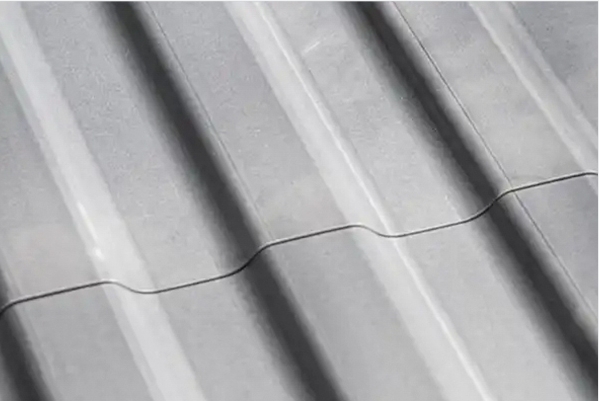

1. High-Strength Steel Construction

Galvanized and coated steel resists rust and corrosion, even in humid or coastal environments.

Thicker gauge metals are used in high-stress areas to prevent warping or structural fatigue.

Reinforced seams and joints enhance structural integrity under heavy grain loads.

2. Advanced Protective Coatings

Epoxy and polymer-based coatings provide an extra barrier against moisture, chemicals, and UV damage.

Ceramic-infused paints reflect heat, reducing thermal expansion stress on storage bins.

Abrasion-resistant finishes protect against wear from grain movement and cleaning processes.

3. Improved Roof and Floor Designs

Conical and arched roofs prevent water pooling and reduce snow load stress.

Reinforced flooring systems with sealed seams prevent moisture seepage and pest entry.

Sloped floors facilitate complete grain unloading, minimizing residue buildup.

4. Corrosion-Resistant Fasteners and Hardware

Stainless steel bolts and brackets prevent rust-related failures.

Sealed gaskets and weatherproof seals keep moisture and pests out of critical joints.

5. Enhanced Structural Support Systems

Heavy-duty hopper bases distribute weight evenly, reducing ground pressure.

Internal bracing and ribbed walls improve resistance to wind and seismic forces.

Modular interlocking panels allow for expansion without compromising stability.

6. Rigorous Testing and Quality Control

Load testing simulates extreme grain weights to ensure structural safety.

Environmental stress tests expose materials to temperature swings, humidity, and salt spray.

Computer-aided design (CAD) modeling predicts weak points before production.

7. Long-Term Maintenance Solutions

Removable inspection panels allow for easy internal checks and repairs.

Modular replacement parts extend the lifespan of aging storage systems.

Manufacturer warranties back durability claims, ensuring accountability.

Conclusion

By leveraging stronger materials, smarter engineering, and rigorous testing, manufacturers are producing grain storage solutions that last longer and perform better under demanding conditions. These advancements help farmers and agribusinesses minimize maintenance costs, avoid unexpected failures, and protect their grain investments for years to come.