Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Aug 09, 2025 Visit:52 Source:Roll Forming Machine Factory

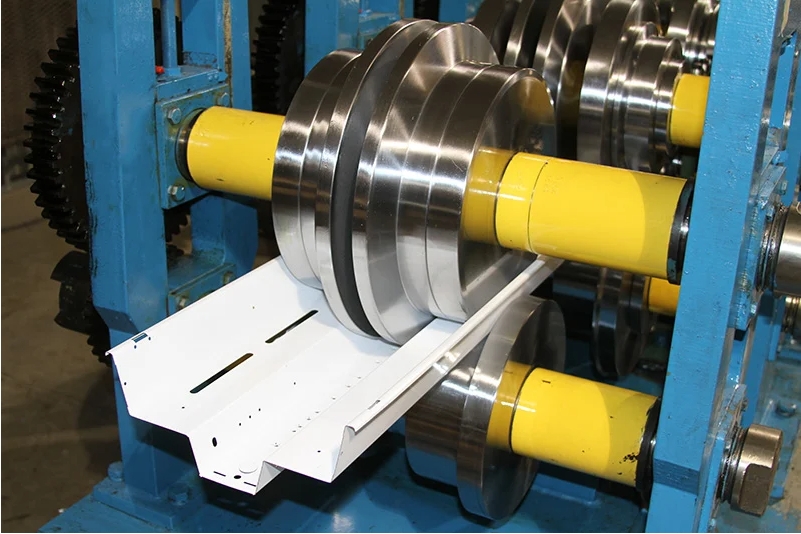

In the lighting industry, quality, efficiency, and precision are critical factors that determine the performance and cost-effectiveness of lighting components. Precision roll forming technology has emerged as a game-changer, enabling manufacturers to produce complex, high-quality parts with greater speed and consistency. But how exactly are precision roll formers revolutionizing lighting component manufacturing?

1. High Accuracy for Complex Profiles

Lighting components often require intricate shapes to accommodate wiring, heat dissipation, and mounting features. Precision roll formers excel at producing these complex profiles with tight tolerances. Advanced roll tooling and CNC controls ensure each piece meets exact specifications, reducing the need for secondary processing or adjustments.

2. Increased Production Speed and Efficiency

Roll forming is a continuous bending process, which allows for rapid production of long strips of metal with minimal waste. Precision roll formers optimize this process by integrating high-speed operations and automated material feeding, dramatically increasing throughput. This enables lighting manufacturers to meet large-volume demands without sacrificing quality.

3. Consistent Quality and Repeatability

With manual or less advanced forming methods, variations in component dimensions can occur, leading to assembly issues or product failures. Precision roll forming provides consistent, repeatable results by minimizing human intervention and automating critical steps. This consistency enhances product reliability and reduces costly rework or scrap.

4. Material Versatility

Lighting components are made from various materials such as aluminum, steel, and specialty alloys, each with different properties. Precision roll formers are designed to handle a wide range of metals while maintaining profile accuracy. This flexibility allows manufacturers to select optimal materials for performance and cost.

5. Integration with Downstream Processes

Modern precision roll forming lines can be combined with additional processing such as punching, notching, or embossing. This integration streamlines production by delivering ready-to-assemble components, reducing handling times, and lowering overall manufacturing costs.

6. Reduced Tooling Costs and Faster Changeovers

The use of modular and adjustable tooling in precision roll forming enables manufacturers to switch between different lighting component profiles more quickly. This adaptability reduces downtime and tooling expenses, allowing companies to respond faster to market trends and custom orders.

Conclusion

Precision roll formers are transforming lighting component manufacturing by delivering superior accuracy, faster production speeds, and enhanced material versatility. Their ability to produce complex, high-quality parts consistently makes them indispensable in meeting today’s lighting industry demands. For lighting manufacturers aiming to improve efficiency and product quality, investing in precision roll forming technology represents a strategic step forward.