Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:May 14, 2025 Visit:80 Source:Roll Forming Machine Factory

For small metalworking shops and home-based fabricators, finding equipment that balances capability with affordability has always been a challenge. The gutter roll forming machine, often overlooked in industrial discussions, might hold unexpected potential for these smaller operations.

Understanding the Basics

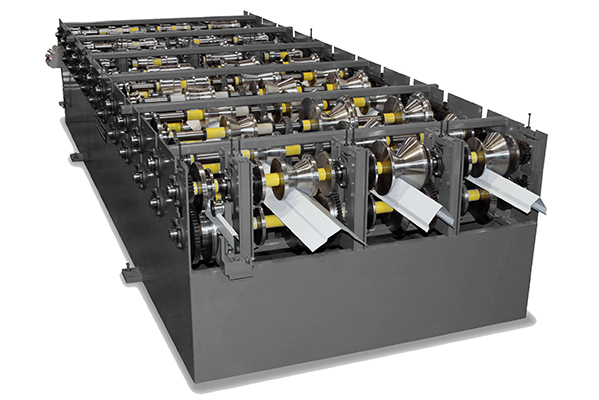

A gutter roll forming machine is a specialized piece of equipment that shapes flat metal sheets into gutters through a series of rollers. Unlike large industrial machines designed for mass production, newer compact models are appearing that cater specifically to small-batch needs.

Why This Matters for Small Operators

Small fabrication businesses and independent metalworkers often face hurdles when taking on gutter-related projects. Traditional methods require either expensive machinery or labor-intensive manual work. A properly designed compact gutter roll former could bridge this gap by offering:

Reasonable initial investment compared to industrial machines

Flexibility for custom gutter profiles

Space-efficient operation suitable for limited workshop areas

Reduced material waste compared to manual forming methods

Practical Considerations

When evaluating gutter roll forming machines for small-scale use, several factors come into play:

Adaptability: Machines that can handle different metal gauges and adjust for various gutter sizes offer more value.

Ease of Operation: Simplified controls reduce the learning curve for operators without specialized training.

Maintenance Requirements: Designs with easily accessible components simplify upkeep for shops without dedicated maintenance staff.

Production Speed: While not matching industrial output, adequate speed for small orders makes the investment worthwhile.

Market Potential

The demand for custom gutters in residential and small commercial projects continues steadily. A machine that enables local fabricators to compete on quality while maintaining reasonable pricing could find a solid market position. This is particularly relevant in areas where:

Architectural styles require non-standard gutter profiles

Replacement projects need matching of existing gutter designs

Specialty materials (like colored or coated metals) are preferred

Challenges to Consider

Like any equipment investment, small-scale gutter roll formers come with considerations:

Upfront costs must align with projected workload

Storage requirements for raw materials and finished products

Market education about the advantages of custom-formed versus pre-made gutters

Looking Ahead

As manufacturing technology becomes more accessible, the potential for specialized equipment like compact gutter roll forming machines to impact small fabrication businesses appears promising. The key lies in designs that genuinely address the needs of smaller operations without compromising on essential functionality.

For metalworkers considering this path, thorough research into available options and honest assessment of business needs will determine whether such equipment could be a valuable addition to their workshop capabilities.