Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:May 21, 2025 Visit:65 Source:Roll Forming Machine Factory

When planning industrial manufacturing projects that require durable metal components, many professionals consider heavy gauge roll forming equipment as a potential solution. This specialized machinery offers distinct advantages for producing strong, consistent metal profiles across various industries.

Understanding Heavy Gauge Roll Forming Equipment

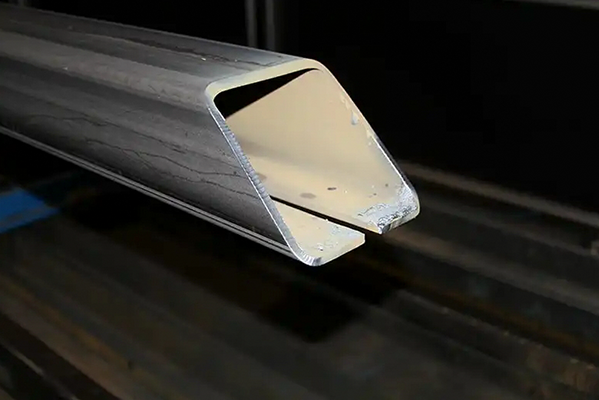

Heavy gauge roll forming equipment refers to industrial machinery designed to shape thicker metal sheets (typically ranging from 3mm to 12mm or more) into continuous profiles with consistent cross-sections. Unlike standard roll formers that handle lighter materials, these robust systems incorporate reinforced components to withstand the higher pressures required for working with substantial metal gauges.

Key Capabilities of Heavy Gauge Roll Forming Systems

Modern heavy gauge roll forming machines demonstrate several important characteristics:

Ability to process high-strength materials including carbon steel, stainless steel, and certain aluminum alloys

Capacity to maintain precise tolerances even with thicker material inputs

Flexibility to produce various profile shapes including channels, angles, and custom configurations

Integration options with punching, notching, and cutting systems for complete processing

Industries That Benefit From Heavy Gauge Solutions

Several sectors regularly utilize heavy gauge roll forming equipment for their manufacturing needs:

Construction and Infrastructure: For structural components like beams, purlins, and framing elements

Transportation: Production of truck rails, trailer components, and heavy vehicle parts

Industrial Equipment: Manufacturing of machine frames, supports, and protective enclosures

Energy Sector: Creation of transmission poles, turbine components, and structural supports

Assessing Project Compatibility

When determining if heavy gauge roll forming equipment suits your project, consider these factors:

Material Specifications: Thickness and type of metal required for your components

Production Volume: Expected quantities and production run frequencies

Profile Complexity: Design requirements for cross-sectional shapes and dimensional accuracy

Secondary Operations: Need for additional processing like hole patterns or special finishes

Advantages Over Alternative Methods

Compared to other metal forming approaches, heavy gauge roll forming offers:

Consistent quality across long production runs

Efficient material usage with minimal waste

Lower per-unit costs for medium to high volume production

Reduced secondary operations through inline processing capabilities

Technical Considerations

Proper implementation of heavy gauge roll forming requires attention to:

Tooling design optimized for specific material thicknesses

Machine rigidity to prevent deflection under high pressures

Power requirements sufficient for continuous operation

Maintenance protocols to ensure long-term performance

Future Developments in Heavy Gauge Technology

Manufacturers continue to enhance heavy gauge roll forming equipment with:

Improved control systems for greater precision

Advanced monitoring capabilities for quality assurance

Quick-change tooling systems for increased flexibility

Energy-efficient drive systems without compromising performance

For projects requiring durable metal components with consistent profiles, heavy gauge roll forming equipment often provides an effective manufacturing solution. By carefully evaluating your specific requirements against the capabilities of modern systems, you can determine whether this technology aligns with your production needs. Many operations find that the combination of strength, precision, and efficiency makes heavy gauge roll forming a practical choice for their applications.