Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:May 06, 2025 Visit:81 Source:Roll Forming Machine Factory

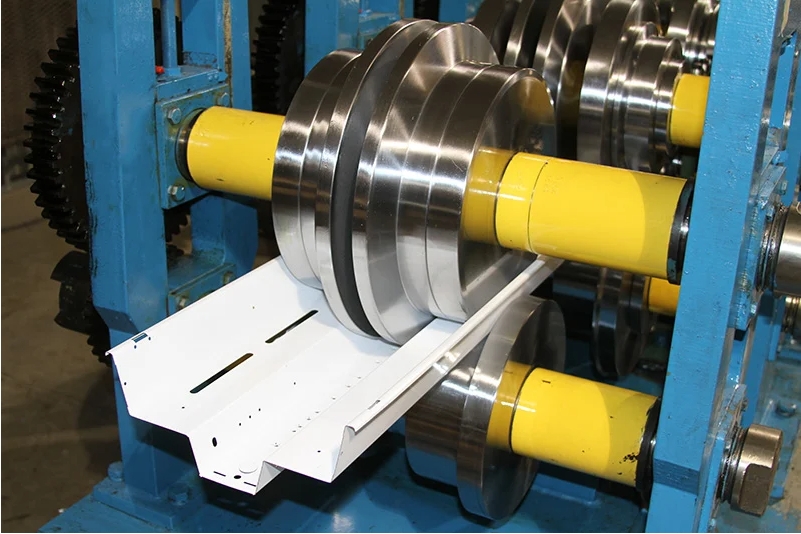

Walk into any metal fabrication shop that's upgraded to modern roll forming equipment, and you'll notice something different - things just seem to move smoother. These aren't your grandfather's metal shaping machines. Today's advanced roll formers are making a real difference in how efficiently shops can operate. Let's look at how.

1. Less Waiting, More Producing

Remember how older machines needed constant tweaking and adjustment? Newer models have solved this headache. With improved control systems and automatic adjustments, operators spend less time fiddling with settings and more time making parts. One shop owner told us, "It's like going from a car that needs constant tuning to one that just runs right."

2. Fewer Mistakes, Less Waste

We've all seen how one small error can ruin a whole batch of parts. Advanced roll formers now come with built-in quality checks that catch problems immediately. Laser sensors and cameras monitor the forming process in real-time, spotting issues before they become expensive mistakes.

3. Quick Changeovers Keep Jobs Moving

Switching from making one part to another used to mean hours of downtime. New quick-change systems have cut this time dramatically. Some shops report changing over in 15 minutes what used to take two hours. That's more productive hours in every workday.

4. They're Easier to Run Than You Might Think

There's a misconception that advanced machines require PhDs to operate. Actually, modern interfaces are more intuitive. Touchscreen controls with visual guides help new operators get up to speed faster. As one first-time operator put it, "If you can use a smartphone, you can learn to run this."

5. They Play Well With Other Equipment

Today's roll formers don't work in isolation. They connect seamlessly with cutting, punching, and finishing stations down the line. This integration creates a smooth workflow where metal goes in one end and finished parts come out the other with minimal handling.

Real-World Results

Shops using these advanced machines typically see:

More parts produced per shift

Less material wasted

Fewer delays from setup changes

Reduced need for reworks

One manufacturer summed it up: "We're not working harder - we're working smarter. The machine handles the precision work, and our team focuses on keeping production moving."

Is It Right for Your Shop?

While these machines aren't cheap, many shops find the investment pays off faster than expected through increased output and reduced operating costs. The key is matching the machine's capabilities to your specific production needs.

For metalworking businesses feeling the squeeze of tight deadlines and thin margins, these advanced roll forming machines are proving to be valuable teammates in the daily production race. They won't replace skilled workers, but they are helping those workers achieve more with their time and materials.

Have you considered upgrading your forming equipment? What efficiency challenges are you facing in your metalworking operations? Let's talk shop - drop us a line with your thoughts.