Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:May 08, 2025 Visit:90 Source:Roll Forming Machine Factory

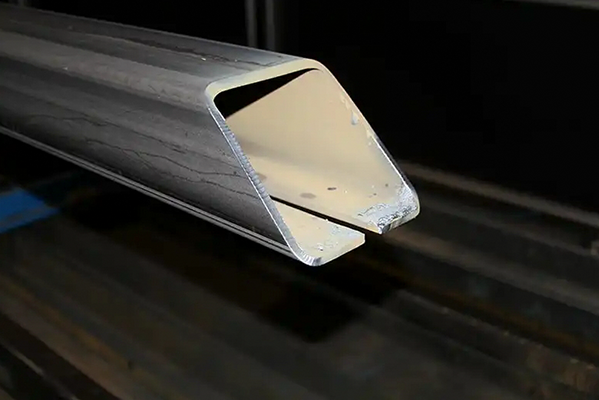

Roll forming machines have long been a staple in metal fabrication, shaping coils of metal into precise profiles with consistent quality. But as industries demand more intricate and specialized metal parts, the question arises: Can traditional roll forming technology handle today’s complex designs?

The Evolution of Roll Forming

Roll forming isn’t new—it’s been around for decades, efficiently producing everything from simple gutters to structural steel components. The process works by gradually bending metal through a series of rollers, each step bringing the material closer to the final shape. For straightforward profiles, it’s a fast and cost-effective method.

However, modern applications often require more than just basic channels or angles. Industries like automotive, aerospace, and construction now need profiles with tight tolerances, multi-curved designs, and integrated features such as embossing or pre-punched holes.

Challenges with Complex Profiles

Not all roll forming machines are created equal. Older or less advanced models may struggle with:

Tight bends and intricate geometries – Some machines can’t achieve sharp angles without wrinkling or distorting the metal.

Variable material thickness – Forming profiles that transition between thick and thin sections requires precise control.

High-strength metals – Advanced alloys and high-tensile steels demand stronger machinery to avoid springback issues.

How Modern Machines Are Adapting

Thankfully, roll forming technology has improved to meet these demands. Here’s how:

Computer-Aided Design (CAD) Integration – Engineers can now simulate the forming process before production, reducing trial and error.

Servo-Driven Rollers – These allow for real-time adjustments, improving accuracy for complex shapes.

Hybrid Systems – Some machines combine roll forming with punching, laser cutting, or welding in a single pass, streamlining production.

Better Tooling Materials – High-grade dies and rollers last longer and maintain precision, even with tough metals.

Is Roll Forming Still the Right Choice?

For many manufacturers, the answer is yes—especially when high volume and consistency matter. While processes like extrusion or stamping have their place, roll forming remains a reliable option for long runs of custom profiles.

That said, not every shop has the latest equipment. If a project calls for highly complex shapes, it’s worth consulting with manufacturers to ensure their machines are up to the task.

Final Thoughts

Roll forming machines have come a long way, and many now handle far more than simple strips of metal. While challenges remain for extreme designs, ongoing advancements mean this trusted method isn’t going away anytime soon. For businesses needing precision-formed metal parts, the key is finding the right equipment—and the right partner—to get the job done.