Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Aug 13, 2025 Visit:54 Source:Roll Forming Machine Factory

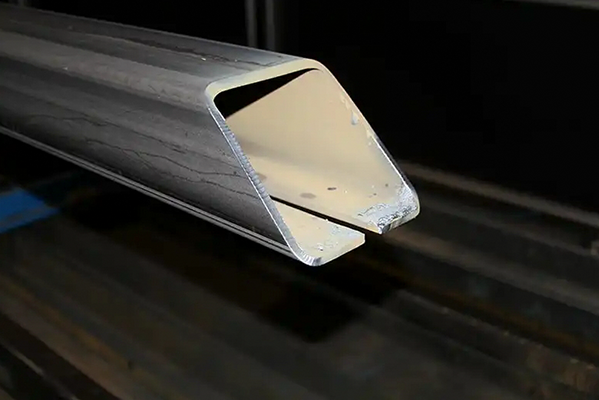

In industrial manufacturing, processing the maximum allowable material thickness on a daily basis requires both precision and durability. High-strength rollformers are specifically designed to handle these demands, ensuring consistent production without compromising equipment performance.

1. Engineered for Structural Stability

High-strength rollformers feature reinforced frames and heavy-duty stands that maintain alignment when working with thick, rigid materials. This stability prevents deformation during forming and supports accurate profile production.

2. Optimized Drive and Power Systems

The motors, gearboxes, and transmission components in these machines are designed to deliver the torque required for thicker metals. This ensures smooth feeding and forming, even at higher loads.

3. Precision Tooling for Consistent Output

Custom-engineered rollers and tooling maintain tight tolerances across the full range of material thicknesses. This precision reduces variation, minimizes scrap, and supports repeatable quality.

4. Cooling and Lubrication Support

When working with thicker materials, friction and heat can affect tooling life and finish quality. Many high-strength rollformers incorporate targeted lubrication and cooling systems to protect components during extended runs.

5. Built for Continuous Operation

Key parts such as bearings, shafts, and forming dies are selected for their ability to withstand high loads over prolonged periods. This ensures that daily production at maximum thickness does not lead to premature wear.

Conclusion

High-strength rollformers are equipped with the structural reinforcement, power capacity, and precision tooling needed to process maximum material thickness consistently. By combining robust construction with advanced engineering, they support reliable, high-quality production in demanding manufacturing environments.