Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Jun 19, 2025 Visit:82 Source:Roll Forming Machine Factory

Yes, purlin roll forming equipment is very much adapting to evolving production demands, driven by the constant need for greater efficiency, versatility, and responsiveness in the construction and manufacturing sectors. Modern machinery incorporates significant advancements that directly address these changing requirements.

Enhanced Versatility and Quick Changeovers

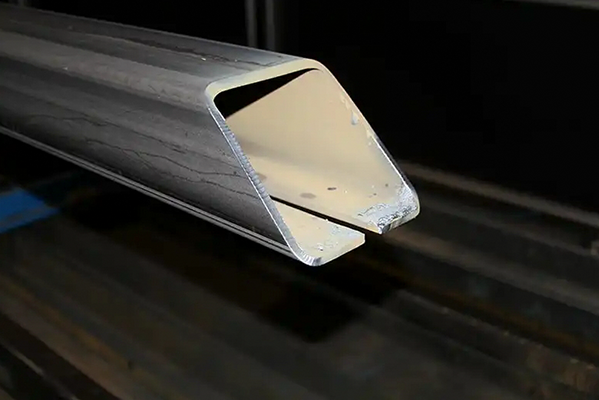

One of the most significant adaptations is the move towards greater versatility. Historically, purlin roll formers might have been dedicated to producing a single size or profile (e.g., only C-purlins of a specific dimension). Today, manufacturers demand machines capable of producing a wide array of purlin profiles—C, Z, U, and sigma—and a vast range of sizes, often on the same machine.

Crucially, these machines are designed for rapid changeovers. Thanks to advanced automation and control systems, switching between different purlin shapes and dimensions can be accomplished in minutes, sometimes with just a few button presses on an intuitive HMI. This drastically reduces downtime and allows for agile production schedules, enabling manufacturers to fulfill diverse orders quickly without extensive retooling.

Increased Automation and Precision

The drive for higher productivity and fewer errors has led to a major increase in automation and precision. Current purlin roll formers integrate sophisticated Computerized Numerical Control (CNC) systems that manage the entire forming process. This digital control ensures consistent accuracy in dimensions, hole placement, and cut lengths, minimizing material waste and eliminating the need for manual adjustments.

Furthermore, features like servo-driven motors and real-time sensing contribute to this precision. Servo motors offer superior control over movements, particularly in cutting and punching, ensuring every component is identical. Sensors continuously monitor the process, allowing the system to make instantaneous corrections, thus maintaining quality even at high production speeds.

Integration with Digital Workflows

Modern production demands also include seamless data flow and process optimization. Purlin roll forming equipment is adapting by integrating with broader digital workflows. This means machines can often directly import design specifications from CAD software, reducing manual data entry and potential errors. Some systems even offer remote monitoring and diagnostic capabilities, allowing manufacturers to track performance, predict maintenance needs, and troubleshoot issues from off-site. This level of connectivity enhances overall operational efficiency and strategic planning.

Higher Throughput and Material Optimization

Evolving demands often equate to a need for higher throughput. Manufacturers are pushing for faster machines that can produce more purlins in less time. Simultaneously, there's a strong focus on material optimization. Advanced cutting technologies, like "infinite shearing," allow for precise cuts that minimize scrap, contributing to cost savings and more efficient use of raw materials. This dual focus on speed and efficiency is a direct response to competitive market pressures.

In conclusion, purlin roll forming equipment is not just keeping pace with evolving production demands; it's actively shaping them. Through continuous innovation in automation, versatility, precision, and digital integration, these machines empower manufacturers to meet increasingly complex and time-sensitive project requirements with remarkable efficiency and accuracy.