Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Jun 18, 2025 Visit:68 Source:Roll Forming Machine Factory

The construction industry is in a constant state of evolution, driven by technological advancements, shifting project demands, and the relentless pursuit of greater efficiency. In this dynamic environment, the equipment used for metal building and roofing projects must also adapt. The question arises: is current metal building and roofing equipment meeting these changing needs?

The answer, broadly speaking, is a resounding yes, though with continuous room for innovation. Manufacturers of this specialized equipment are demonstrably responding to key trends within the construction sector.

Precision and Speed

One significant shift in construction is the demand for enhanced precision and increased speed. Modern metal building and roofing projects often involve complex designs and tight deadlines. Equipment manufacturers have addressed this by developing machinery that offers greater accuracy in cutting, forming, and seaming. Automated and semi-automated systems are becoming more prevalent, reducing reliance on manual processes and minimizing human error. This not only improves the quality of the final product but also significantly accelerates project timelines.

Versatility in Fabrication

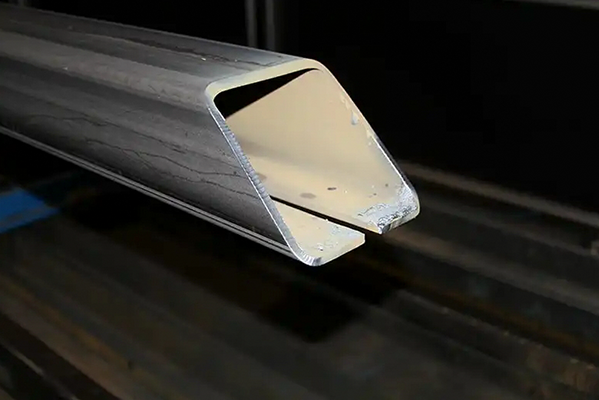

Another crucial aspect is the need for versatility in fabrication. Construction projects rarely involve a "one-size-fits-all" approach. Equipment capable of handling a wider range of material gauges, profiles, and panel lengths is increasingly vital. We're seeing more adaptable rollforming machines, brakes, and shears that can be quickly reconfigured for different specifications. This flexibility allows contractors to take on a broader array of projects without needing to invest in a vast collection of single-purpose machines.

Operational Efficiency

The drive for operational efficiency is paramount. This translates to equipment that is more intuitive to operate, requires less frequent maintenance, and can perform multiple functions. Manufacturers are integrating advanced controls and diagnostic tools into their machinery, making it easier for operators to manage tasks and troubleshoot issues. Furthermore, designs that prioritize quick setup and teardown contribute significantly to overall project flow, especially on sites where space and time are at a premium.

Safety Enhancements

Finally, a continued focus on safety enhancements remains a core driver. Equipment is continually being refined with features that protect workers and prevent accidents. This includes improved guarding, emergency stop mechanisms, and ergonomic considerations in machine design. A safer work environment not only protects personnel but also contributes to greater productivity and project continuity.

In conclusion, the metal building and roofing equipment sector is actively engaged in meeting the evolving demands of the construction industry. Through continuous improvements in precision, versatility, operational efficiency, and safety, the tools of the trade are proving capable of supporting the complex and fast-paced nature of modern construction projects. As the industry continues its forward momentum, we can anticipate further advancements that will empower even more efficient and sophisticated building solutions.